gold mining equipment manufacturers sa

Engineering Resilience and Profitability in Demanding Applications: A Technical Review of Advanced Comminution Solutions

1. The Operational Bottleneck: The High Cost of Inefficient Size Reduction

On any given day, my primary concern as a plant manager is the relentless pressure of operational costs. A significant and often underestimated drain on profitability originates in the comminution circuit. Consider a typical challenge: processing a highly abrasive gold ore with significant silica content. The primary crusher discharge is inconsistent, leading to an inefficient feed size distribution for the SAG mill. This inconsistency forces the grinding circuit to work harder, escalating energy consumption and accelerating mill liner wear.

The data is unequivocal. A study by the Coalition for Eco-Efficient Comminution (CEEC) underscores that grinding alone can account for over 50% of a mine's total energy consumption. This statistic highlights a critical truth: the efficiency of every downstream process is dictated by the performance of the primary and secondary crushing stages. The core problems we face are multifaceted:

- Low Overall Recovery Rates: Poorly sized feed material creates a bottleneck in liberation, preventing optimal reagent contact in leach circuits.

- Excessive Wear Part Consumption: Abrasive ores rapidly degrade crusher mantles, concaves, and jaw plates, leading to frequent, costly shutdowns and high inventory carrying costs for spare parts.

- Inconsistent Product Gradation: A high proportion of flaky or elongated particles in the crusher product can reduce material flowability, increase power draw in mills, and ultimately diminish final product quality.

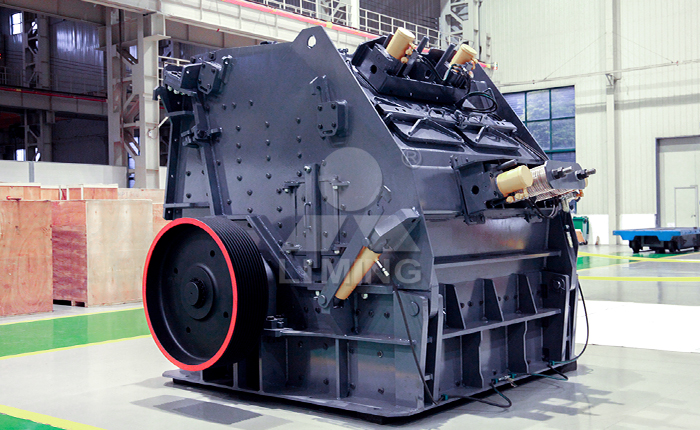

2. The Engineering Solution: Precision-Engineered Crushing for Superior Performance

Addressing these bottlenecks requires a shift from simply purchasing machinery to implementing engineered solutions. The focus must be on crushers designed with a fundamental understanding of kinematics and chamber dynamics. Modern cone crushers, for instance, are a testament to this philosophy.

The engineering principles revolve around several key aspects:

- Advanced Crushing Chamber Design: Optimized geometry ensures inter-particle crushing, where rocks crush each other, rather than simply being compressed against liners. This significantly improves efficiency and produces a more cubical product.

- Hydraulic System Intelligence: Modern systems do more than just clear blockages. They allow for dynamic adjustment of the Closed-Side Setting (CSS) during operation to compensate for liner wear, maintaining a consistent product size distribution throughout the liner's life.

- Wear Material Science: The use of premium alloys, tailored to specific ore abrasion characteristics, is non-negotiable. Zirconium-based alloys or specially hardened manganese steels can extend operational cycles by hundreds of hours.

The following table contrasts the performance of a next-generation cone crusher against conventional technology in a hard rock application:

| Key Performance Indicator (KPI) | Conventional Cone Crusher | Next-Generation Cone Crusher |

|---|---|---|

| Throughput (tph) | Baseline | +15% to +25% |

| Product Shape (% Cubical) | 60-70% | 80-85%+ |

| Liner Life (Hours) | 800 - 1,000 | 1,300 - 1,600 |

| Specific Energy Consumption (kWh/t) | Baseline | -10% to -15% |

| Operational Availability | ~92% | ~96% |

3. Proven Applications & Economic Impact: Maximizing Yield Across Diverse Material Profiles.jpg)

The versatility of well-engineered equipment is proven through its application across different challenges.

-

Application 1: Copper Ore for Optimal Leach Recovery

- Challenge: A porphyry copper operation needed a finer, more consistent feed for its heap leach pads to maximize mineral exposure and recovery rates.

- Solution: Implementation of a multi-cylinder hydraulic cone crusher in closed circuit with a screen.

- Results:

- Quality Improvement: Achieved a P80 of 12mm with over 80% cubical product, creating optimal permeability for leach solution.

- Recovery Increase: Improved copper recovery by 3-5% due to superior particle size distribution.

- Cost Reduction: Reduced cost per ton by 12% through longer wear part intervals and lower recirculating load.

-

Application 2: Railway Ballast from Granite

- Challenge: Producing high-integrity, single-size ballast stone that meets strict geometric specifications for rail infrastructure.

- Solution: Deployment of a high-performance jaw crusher paired with a vertical shaft impactor (VSI) for final shaping.

- Results:

- Quality Improvement: Consistently produced over 95% crushed cubical product, exceeding rail specification requirements.

- Throughput Increase: Achieved a 20% increase in tons per hour due to optimized flow and reduced clogging in the VSI.

- Value Addition: Commanded a premium price for consistently high-specification material.

4. The Strategic Roadmap: Integrating Digitalization and Sustainable Practices

The future of mining equipment lies not only in mechanical robustness but also in digital intelligence and sustainability. The strategic roadmap involves:

- Integration with Plant Process Optimization Systems: Crushers are no longer isolated units. They are data nodes that feed real-time information on power draw, pressure, and cavity level into a central system for dynamic process adjustment.

- Predictive Maintenance Algorithms: By analyzing trends in hydraulic pressure and motor power draw, advanced systems can predict liner wear and component failure weeks in advance, transforming maintenance from reactive to planned.

- Designs for Sustainability: This includes facilitating the use of recycled wear materials in liner manufacturing and designing systems that operate at lower decibel levels and with improved dust suppression capabilities.

5. Addressing Critical Operational Concerns (FAQ)

-

Q: "What is the expected liner life in hours when processing highly abrasive iron ore?"

- A: For an ultra-abrasive taconite or banded iron formation ore using Zirconium-enhanced liners, expect between 1.2 to 1.8 million metric tons throughput or approximately 1,500-2,200 operational hours. Key influencing factors include feed size distribution (% fines), closed-side setting (CSS), and feed rate consistency.

-

Q: "How does your mobile rock crusher setup time compare to traditional stationary plants?"

- A: A fully independent mobile crushing train (jaw + cone + screen) can be operational on a prepared pad within 48 hours from arrival on site with minimal foundation work required—a fraction of the time needed for civil works associated with stationary plants—with an average crew requirement of three personnel.

-

Q: "Can your grinding circuit handle variations in feed moisture without compromising output?"

A: Advanced grinding mills equipped with variable frequency drives (VFDs) and automated feed control systems can dynamically adjust mill speed and charge volume to maintain optimal performance despite moisture fluctuations up to 8-10%. For higher moisture levels integrated drying systems are recommended upstream

6 Case Study Southeast Asia Barite Processing Co

Client Profile Southeast Asia Barite Processing Co upgrading their facility supply oilfield drilling market

**Specific Challenge Their existing roller mill circuit struggled produce consistent volume API spec barite ground fineness mesh resulting frequent product rejection lost contracts Primary issues were low system availability due mechanical failures inability control heat generation affecting product quality

**Deployed Solution Turnkey grinding circuit featuring high efficiency vertical shaft impactor VSI tertiary crushing stage ensure consistent sub mm feed paired modern ring roller mill integrated air classifier advanced cooling system

Measurable Outcomes

Product Fineness Consistently achieved target fineness minimum mesh residue

System Availability Increased operational availability from improved mechanical reliability predictive monitoring

Energy Consumption Reduced specific energy consumption kWh ton processed through optimized particle size distribution pre grinding stage efficient mill drive

Return Investment ROI Timeline Full project payback achieved within months due increased production capacity premium product pricing reduced waste