conveyor belt matl for stone indusrty

1. PAIN-POINT DRIVEN OPENING

Your primary crushing circuit is a profit center, but your conveyor belt system can be a persistent source of cost and downtime. In the demanding stone industry, standard conveyor belt materials are often insufficient, leading to recurring operational challenges:

- Premature Belt Failure: Sharp, abrasive aggregates like granite, trap rock, and limestone slice and gouge standard rubber covers. This leads to costly, unplanned belt replacements every 12-18 months instead of achieving a 3-5 year service life.

- Excessive Carryback & Spillage: Ineffective cleaning allows fine stone dust and chips to adhere to the belt return. This material builds up, causing mis-tracking, roller damage, and creating hazardous cleanup requirements, increasing labor costs by an estimated 15-20%.

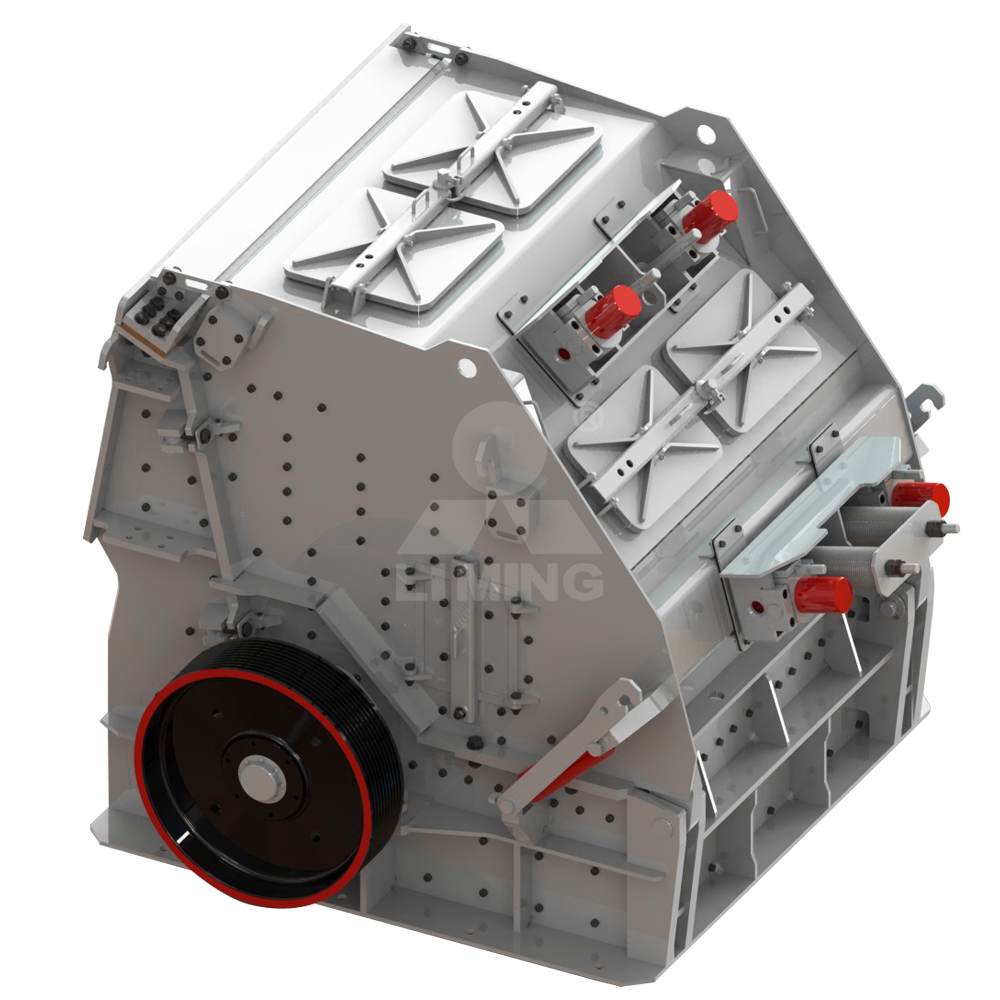

- Impact Damage at Load Zones: The repeated impact of large, heavy stone from crushers or screens creates rips, tears, and ply separation at transfer points. This damage necessitates immediate shutdowns for repair or patching.

- Inconsistent Performance in Variable Conditions: From wet processed stone to dry, dusty environments, a single belt material rarely performs optimally across all seasons and material types.

Are you managing these issues through constant maintenance budgets and accepting production delays? What if your conveyor belt material was engineered as a durable component of your process flow?

2. PRODUCT OVERVIEW: Heavy-Duty Conveyor Belt Solutions for the Stone Industry

This product line comprises engineered conveyor belting specifically designed for the aggregate and dimension stone sectors. These are not commodity belts but integrated systems built to handle sharp edges, high abrasion, and heavy impact loads.

Operational Workflow:

- Specification: Our engineering team reviews your specific material (e.g., crushed basalt vs. washed gravel), lump size, incline angles, and transfer point dynamics.

- Fabric Selection: A high-tensile strength fabric core (e.g., EP or steel cord) is selected based on tension requirements and rip resistance needs.

- Compound Application: A proprietary rubber compound is applied as the top cover—formulated for cut/abrasion resistance—and a secondary compound for the bottom cover to manage friction and wear.

- Vulcanization & Quality Control: The belt is cured under precise heat and pressure. Each batch undergoes testing for tensile strength, adhesion between plies, and cover gauge accuracy.

Application Scope & Limitations:

- Scope: Ideal for primary crusher discharge, main plant feed conveyors, screen feed conveyors, radial stackers handling crushed stone (granite), gravel (sandstone), slag (limestone), recycled concrete/asphalt.

- Limitations: Not designed for extreme temperature applications (>250°F) such as hot slag handling without specific compound modifications. Not suitable for steep inclines (>22°) without specialized cleat profiles.

3. CORE FEATURES

-

Cut & Gouge Resistant Top Cover | Technical Basis: High-density rubber compound with oriented fabric weave reinforcement | Operational Benefit: Dramatically reduces penetration from sharp aggregate edges during loading | ROI Impact: Extends top cover service life by up to 40%, reducing replacement frequency and cost per ton conveyed.

-

Impact-Resistant Cushion Ply | Technical Basis: Energy-absorbing rubber layer integrated between the top cover and carcass | Operational Benefit: Dissipates kinetic energy from falling rock at load zones | ROI Impact: Minimizes ply separation and internal damage; field data shows a 60% reduction in load-point related failures.

-

Low-Friction Bottom Cover | Technical Basis: Specially formulated polymer blend with self-lubricating properties | Operational Benefit: Reduces rolling resistance on idlers and improves belt tracking | ROI Impact: Industry testing demonstrates up to an 8% reduction in drive motor energy consumption over standard belts.

-

Anti-Static & Fire-Resistant Properties | Technical Basis: Conductive elements compounded throughout the belt carcass | Operational Benefit: Mitigates static discharge buildup in dry conditions; meets MSHA/OSHA standards for fire retardancy | ROI Impact: Reduces safety incident risk potential and ensures regulatory compliance without secondary treatments.

-

Superior Rip Resistance | Technical Basis: Transverse steel breaker mesh or high-modulus synthetic rip inserts embedded above the carcass | Operational Benefit: Prevents small tears from propagating into full-width belt failures | ROI Impact: Limits catastrophic damage; typical payback achieved in one avoided major rip event per belt span.

4. COMPETITIVE ADVANTAGES

| Performance Metric | Industry Standard (RMA Grade M) | Our Stone Industry Conveyor Belt Material Solution | Advantage (% Improvement) |

|---|---|---|---|

| Abrasion Loss (mm³) DIN 53516 / ISO 4649 | ≤150 mm³ | ≤90 mm³ | ≥40% Better Wear Resistance |

| Adhesion Strength (N/mm) Ply-to-Cover | ≥8 N/mm | ≥12 N/mm | ≥50% Stronger Bond |

| Maximum Recommended Lump Size (for given tension) | Standard Calculation | +25% Allowance via Impact Ply Design | Enables Higher Capacity or Longer Life |

| Longitudinal Rip Resistance (Test Force) | Minimal / None | >2500 N/mm (with breaker) | Prevents Propagating Failures |

5. TECHNICAL SPECIFICATIONS

- Capacity/Rating: Available in widths from 24" to 96". Working tensions from 220 PIW to over 1500 PIW (steel cord).

- Power Requirements: Directly compatible with existing CEMA-rated drives; reduced rolling resistance can allow for potential motor downsizing in new installations.

- Material Specifications: Top cover thicknesses from 3/16" to 1/2"+ available. Carcass options include EP fabric (2-6 plies) or steel cord (ST630-ST5400). RMA Grade M-AS / FRAS standard; SBR/NR compound blends optimized for mineral service.

- Physical Dimensions: Standard rolls up to 1000 ft; endless spliced lengths available upon request.

- Environmental Operating Range: Designed for ambient temperatures from -10°F to +180°F (-23°C to +82°C). Resists degradation from moisture, UV exposure typical in quarry environments.

6. APPLICATION SCENARIOS

Granite Quarry Primary Circuit | Challenge: A large granite operation experienced catastrophic belt rips every 4-6 months on its primary crusher discharge conveyor due to oversized slabs weighing over 1 ton falling from the jaw crusher.| Solution: Implementation of a steel-cord reinforced conveyor belt material with a full-width steel breaker mesh and a ½” cut-resistant top cover.| Results: The belt has operated for over 36 months without a major failure. Quantifiable outcomes include an elimination of two planned replacement shutdowns per year and a calculated savings of $85k annually in belting and downtime costs.

Recycled Concrete & Asphalt Processing Plant | Challenge: Highly abrasive recycled materials combined with significant carryback created excessive maintenance on return idlers and pulleys at a municipal RAP facility.| Solution: Installation of our multi-ply conveyor belt material featuring an abrasion-resistant top cover with low-adhesion properties designed specifically for recycled aggregates.| Results: Carryback was reduced by an estimated 70%, cutting daily cleanup labor by two hours. Idler replacement intervals extended from quarterly to annually.

7. COMMERCIAL CONSIDERATIONS

Our heavy-duty conveyor belt material solutions are offered in structured tiers:

-

Performance Tier: A robust multi-ply fabric belt with premium cut/gouge resistant covers for general crushed stone applications.

Optional Features: Rip detection sensor loops integrated during manufacture.

Service Package: Includes splice specification support and vulcanizer recommendations. -

Premium Tier: Steel cord or high-modulus fabric belts with integrated transverse/ longitudinal breakers for severe impact applications (primary crushers).

Optional Features: Ceramic lagging on pulley covers pre-fitted at factory.

Service Package: On-site splice supervision by certified technicians.

Financing options include leasing programs that convert capital expenditure into operational expense, as well as bulk purchase agreements across multiple sites with guaranteed pricing.

8. FAQ.jpg)

Q1: Is this conveyor belt material compatible with our existing mechanical fasteners or does it require vulcanized splicing?

A1: It is compatible with both high-quality mechanical fasteners (for emergency repairs) and vulcanized splicing. For optimal performance and longevity in primary applications we recommend vulcanized splices performed by certified technicians using our provided specifications.

Q2: What is the expected operational impact during installation?

A2:Installation time is comparable to standard belting。The key difference is reduced future operational impact。By minimizing unplanned stops,your overall plant availability increases。Proper planning allows installation during scheduled maintenance。

Q3:How do you validate claims about extended service life?

A3:We provide wear rate calculations based on standardized industry tests(DIN,ISO)and reference site data。For critical applications,we can arrange site visits to existing installations handling similar materials。

Q4:Are there different compounds available within this product line?

A4:Yes。We offer several compound formulations optimized for specific conditions—such as highly abrasive dry stone versus wet washed aggregates—to ensure you are not paying for properties you do not need。

Q5:What commercial terms are available?

A5:We offer net-30 terms on approved commercial accounts。Volume-based pricing is available across multiple plant sites,and we provide detailed pro-forma invoices outlining total cost-of-ownership projections。

Q6:Can you assist with technical specifications for our bid packages?

A6:Yes。Our engineering team provides detailed technical data sheets,CAD drawings of recommended pulley configurations,and full specification language suitable for inclusion in RFQs sent to contractors。

Q7:What is your lead time on custom widths or non-standard lengths?

A7:Standard widths(36”,42”,48”)are typically stocked。Custom configurations require an average lead time of 6-8 weeks from order confirmation,subject to project scope。