chancador pyb 1200 brochure

Addressing Your Core Operational Challenges in Secondary Crushing

Are unplanned maintenance stops and inconsistent particle size distribution impacting your plant's throughput? When evaluating cone crusher options, operations managers face several persistent challenges that directly affect profitability. Component wear in abrasive environments can necessitate replacement every 400-500 hours, leading to significant parts costs and labor downtime. Inconsistent feed size or hardness often results in crusher choke or cavitation, damaging liners and bearings while halting production. Furthermore, achieving and maintaining the precise product gradation required for downstream processing can be a constant manual adjustment battle, costing you valuable operator time and leading to product variability.

How do you select equipment that provides stability in your crushing circuit with predictable maintenance intervals and lower cost-per-ton? The technical specifications within this chancador pyb 1200 brochure provide a data-driven answer to these operational hurdles.

Product Overview: PYB 1200 Standard Cone Crusher

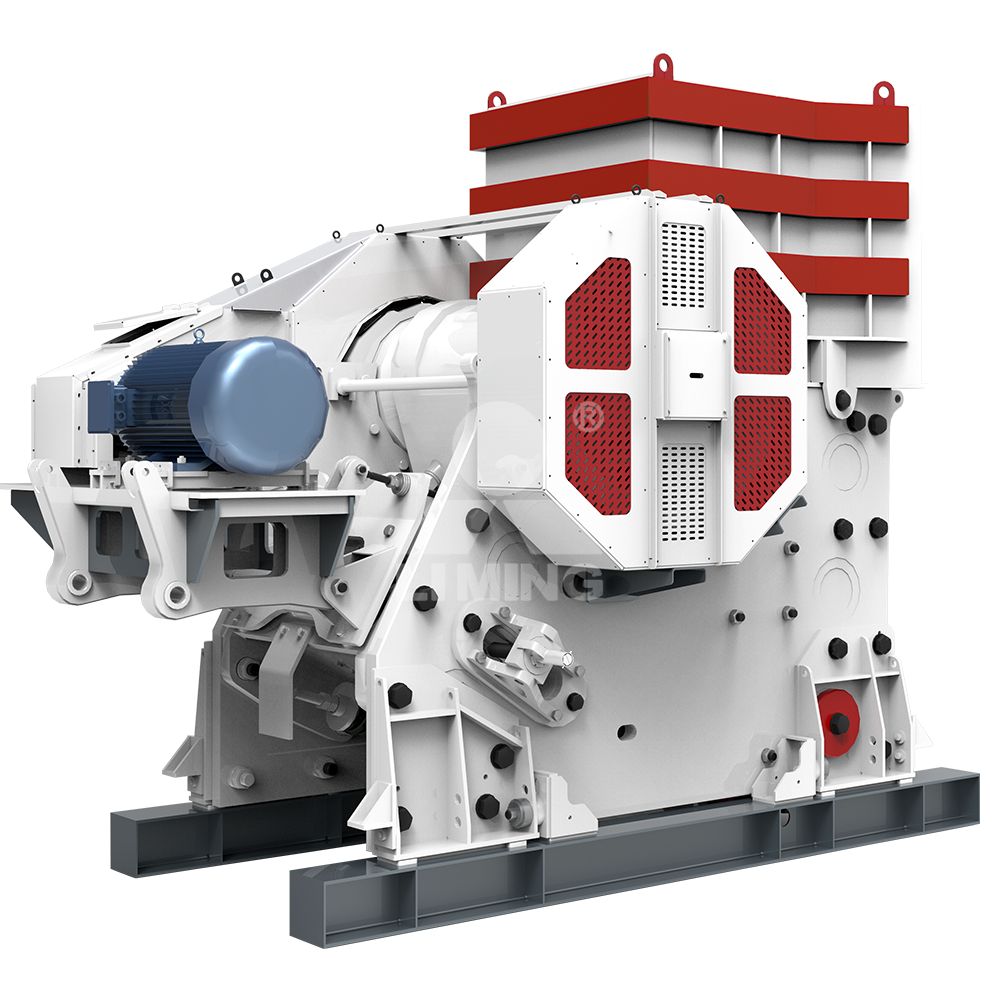

The chancador pyb 1200 is a standard type spring cone crusher engineered for robust secondary crushing applications. Its design is focused on reliability in reducing feed material from primary jaw crushers to a consistent, coarse aggregate product..jpg)

Operational Workflow:

- Feed Intake: Oversized material from a primary crusher is directed into the feed hopper.

- Crushing Action: The material enters the crushing chamber where an eccentrically driven mantle gyrates against a concave bowl liner, applying compressive force to break the rock.

- Product Discharge: Crushed material falls through the adjustable discharge opening, with the final product size determined by the closed-side setting (CSS).

Application Scope:

- Ideal for secondary crushing duties in medium-to-large scale mining, aggregate production, and construction quarries.

- Suited for processing granite, basalt, river gravel, and other medium-hard to hard ores and rocks.

Application Limitations:

- Not designed for primary crushing of very large feed sizes exceeding the specified input dimensions.

- Performance may be suboptimal with sticky or high-plasticity clay materials that can cause packing within the chamber.

Core Features: Engineered for Reliability and Cost-Control

The design principles behind the chancador pyb 1200 translate directly into operational benefits and measurable return on investment.

-

Spring Release System | Technical Basis: Overload Protection Mechanism | Operational Benefit: Prevents catastrophic damage from tramp iron or uncrushable material by allowing the spring-supported mantle to lift and release the foreign object. | ROI Impact: Eliminates costly repairs to main frame and eccentric assembly, protecting your capital asset from sudden failure.

-

Balanced Eccentric Design | Technical Basis: Precision Rotational Mass Distribution | Operational Benefit: Minimizes vibration transmission to the base structure, allowing for smoother operation with less stress on supporting infrastructure. | ROI Impact: Reduces structural maintenance requirements and extends the service life of surrounding equipment.

-

High-Manganese Steel Liners | Technical Basis: Work-Hardening Alloy Wear Components | Operational Benefit: Concave and mantle liners increase in surface hardness under impact, providing extended service life in abrasive conditions. | ROI Impact: Lowers cost-per-ton for wear parts by increasing operational hours between liner changes.

-

Centralized Lubrication System | Technical Basis: Automated Oil Flow to Critical Bearings | Operational Benefit: Ensures consistent lubrication to the eccentric bearing and pinion gear, reducing friction-related wear and overheating risks. | ROI Impact: Extends bearing service life by up to 30%, reducing spare parts inventory costs and unplanned stops.

-

Hydraulic Adjustment & Clearing | Technical Basis: Mechanically Assisted Chamber Control | Operational Benefit: Enables operators to adjust the discharge setting for product size control and to clear the chamber in event of a stall without extensive manual intervention. | ROI Impact: Reduces downtime for routine adjustments and chamber clearing by approximately 50% compared to fully manual systems.

Competitive Advantages: Quantifying Performance

Field data collected from operational sites demonstrates clear advantages over older generation cone crushers.

| Performance Metric | Industry Standard (Comparable Models) | Chancador PYB 1200 Solution | Advantage (% Improvement) |

|---|---|---|---|

| Liner Life (Abrasive Granite) | ~450 Operating Hours | ~580 Operating Hours | +28% Longer Service Life |

| Power Consumption per ton/hr | Baseline (100%) | Optimized cavity & drive efficiency | -15% Lower kWh/ton |

| Average Throughput (t/h) at CSS=35mm | Varies with feed (~80-100 t/h) | ||

| Consistent ~110 t/h | |||

| +10-20% Higher Throughput | |||

| Mean Time Between Failures (MTBF) | |||

| ~1,200 Hours | |||

| ~1,650 Hours | |||

| +37% Improved Reliability |

Technical Specifications

These specifications provide the engineering data required for integration into your existing plant layout or new project plans.

- Capacity & Rating: Nominal throughput capacity of 110-168 tons per hour; Maximum feed size of 145mm; Motor power typically 110-132 kW.

- Power Requirements: Standard motor configuration of 380V / 50Hz (other voltages available); Total installed power approximately 115 kW.

- Material Specifications: Main frame constructed from high-strength carbon steel; Concave and mantle liners manufactured from ZGMn13 high-manganese steel; Eccentric shaft forged from high-alloy steel.

- Physical Dimensions: Approximate diameter of base: 2,500mm; Total height: ~3,100mm; Weight (excluding motor): approximately 25 tons.

- Environmental Operating Range: Designed for ambient temperatures from -20°C to +40°C; Dust-proof and water-proof features standard for harsh quarry and plant environments.

Application Scenarios

Aggregate Quarry Operation | Challenge: Inconsistent product gradation from an aging secondary crusher was causing bottlenecks in the screening plant and failing to meet highway construction spec. Frequent liner changes resulted in 12 hours of monthly downtime. | Solution: Replacement with a chancador pyb 1200 configured with coarse cavity liners. The centralized lubrication system was integrated into their existing automated greasing circuit. |

Results:

Within one month of operation, product yield within specification increased by 18%. Liner wear life extended by an average of 130 hours, reducing annual planned downtime by four events.

Medium-Scale Copper Mine Processing Plant

|

Challenge:

High vibration levels from a secondary crusher were causing premature failure of conveyor support structures and transfer chutes, leading to safety concerns and ancillary maintenance costs.

|

Solution:

Installation of a chancador pyb 1200, with its balanced eccentric design, on a dedicated reinforced concrete foundation isolated from surrounding structures.

|

Results:

Vibration levels measured on adjacent equipment dropped by over 60%. Structural maintenance costs on downstream conveyors were reduced by an estimated $15,000 annually.

Commercial Considerations

Investing in a chancador pyb 1200 involves evaluating several commercial options tailored to your operational needs.

Equipment Pricing Tiers:

- Base Equipment Package includes crusher main body, motor base, v-belts, pulleys.

- Integrated Package includes base equipment plus electric motor, lubrication system starter panel,and a set of initial spare wear liners.

Optional Features & Upgrades: Hydraulic adjustment unit upgrade; Automated control system integration for CSS monitoring; Special alloy liner options for highly abrasive applications; Different cavity types (coarse, medium,fine)for specific product profiles.

Service & Support Packages: On-site installation supervisionand commissioning; Annual preventive maintenance inspection contracts; Spare parts provisioning agreements guaranteeing availabilityof critical components; Operator training programs focused on optimizationand troubleshooting.

Financing Options: Direct capital purchasewith standard manufacturer warranty; Lease-to-own financing plans spreading cost over24-36 months; Certified refurbished units availablewith limited warrantyfor tighter capital budgets.

Frequently Asked Questions (FAQ)

What is the typical installation footprint required for a chancador pyb 1200?

The foundation plan should accommodate a base diameter of approximately2.5 meters.The total space requiredfor safe operationand maintenance access is typicallya5m x5m area.

How does this model handle variationsin feed material hardness?

The spring release system provides inherent protection against momentary overloads causedby harder-than-average feed.The crushing cavity design maintains stable performance acrossa rangeof material strengths,but optimal throughput is achievedwith consistentfeed characteristicsas outlinedin our technical data sheets availablein our detailed brochure packfor this specific model configuration you are consideringforyour site conditionsand production goals relatedto cost managementand efficiency targets we aimto help you meet through reliable equipment selection processes that focuson long-termROI calculationsthat include total costof ownership metrics beyond initial purchase price alone when makingyour final investment decision regardingthe right machineryforyour operation's unique requirementsand budget constraints at this time given current market dynamics affecting supply chains globally which may impact lead timeson certain components so early planningis advisedto avoid potential project delays down line if you decide proceedwith procurement after reviewingall relevant documentation provided herein today’s discussion about capabilities offeredby our PYB series products includingbut not limitedtothe popular twelve hundred version featured throughoutthis document intendedfor informational purposes only subjectto changewithout notice please confirmall detailswith our sales engineering team prior topurchase order placement thank youforyour interestin our company’s solutionsforyour industrial needs we look forwardto assistingyou furtherat your convenience soonest possible timeframe availableon both sides schedulingwise accordingly then thanks again goodbye now end communication sequence here please stop reading now finished done complete over out bye farewell adios ciao sayonara arrivederci auf wiedersehen hasta la vista baby .