chinese mining crusher

The Unseen Engine of Global Development: A Deep Dive into Chinese Mining Crushers

Beneath the surface of the world's infrastructure, from the concrete in our cities to the metals in our technology, lies a fundamental process: the reduction of raw, massive rock into workable aggregate and minerals. At the heart of this process are industrial crushers, and in recent decades, China has emerged not just as a user, but as a dominant global force in their design, manufacturing, and supply. This article explores the ascent of Chinese mining crushers, from their foundational principles to their pervasive global footprint.

I. Industry Background: The Crucible of Demand

China's rise as an industrial superpower is a story written in steel, concrete, and copper. The unprecedented scale of its domestic infrastructure boom—spanning decades and involving entire new cities, thousands of kilometers of high-speed rail, and monumental hydroelectric dams—created an insatiable demand for raw materials. This domestic crucible provided local machinery manufacturers with a unique testing ground.

Unlike manufacturers in established markets who often focused on incremental improvements, Chinese engineers were tasked with solving problems of scale, durability, and cost-efficiency on a level rarely seen before. They had to build machines that could operate 24/7 in remote quarries and harsh mines, processing billions of tons of material. This relentless domestic demand forced rapid innovation cycles and fostered intense competition among hundreds of manufacturers, ultimately forging an industry that was both robust and highly responsive to market needs.

II. Product Core: Deconstructing the Crusher Arsenal

Chinese manufacturers produce a comprehensive range of crushers, covering every stage of the size reduction process. The core philosophy often balances high performance with exceptional value for money.

1. Jaw Crushers: The Primary Workhorse

As the first line of attack in any crushing circuit, Chinese jaw crushers are built for brute force. Key features include:

Robust Frame Construction: Heavy-duty steel plates and reinforced castings ensure structural integrity under extreme shock loads.

Deep Crushing Chambers: Optimized chamber designs allow for higher capacity and a larger feed size, reducing bridging and improving overall efficiency.

Versatile Applications: Ranging from small mobile units for construction debris to colossal stationary crushers for mega-mines.

2. Cone Crushers: The Precision Secondary Crusher

For producing finely crushed, cubical product essential for high-quality concrete and asphalt, cone crushers are critical.

Advanced Eccentric Design: High-precision machining allows for faster rotation speeds (RPM) and higher power levels without sacrificing stability.

Hydraulic Adjustment & Clearing: Modern Chinese cone crushers feature comprehensive hydraulic systems for quick setting adjustments and automatic clearing in the event of an overload (tramp release), minimizing downtime.

Liner Technology: Many manufacturers collaborate with or produce their own high-performance manganese steel liners, optimizing wear life and crushing efficiency.

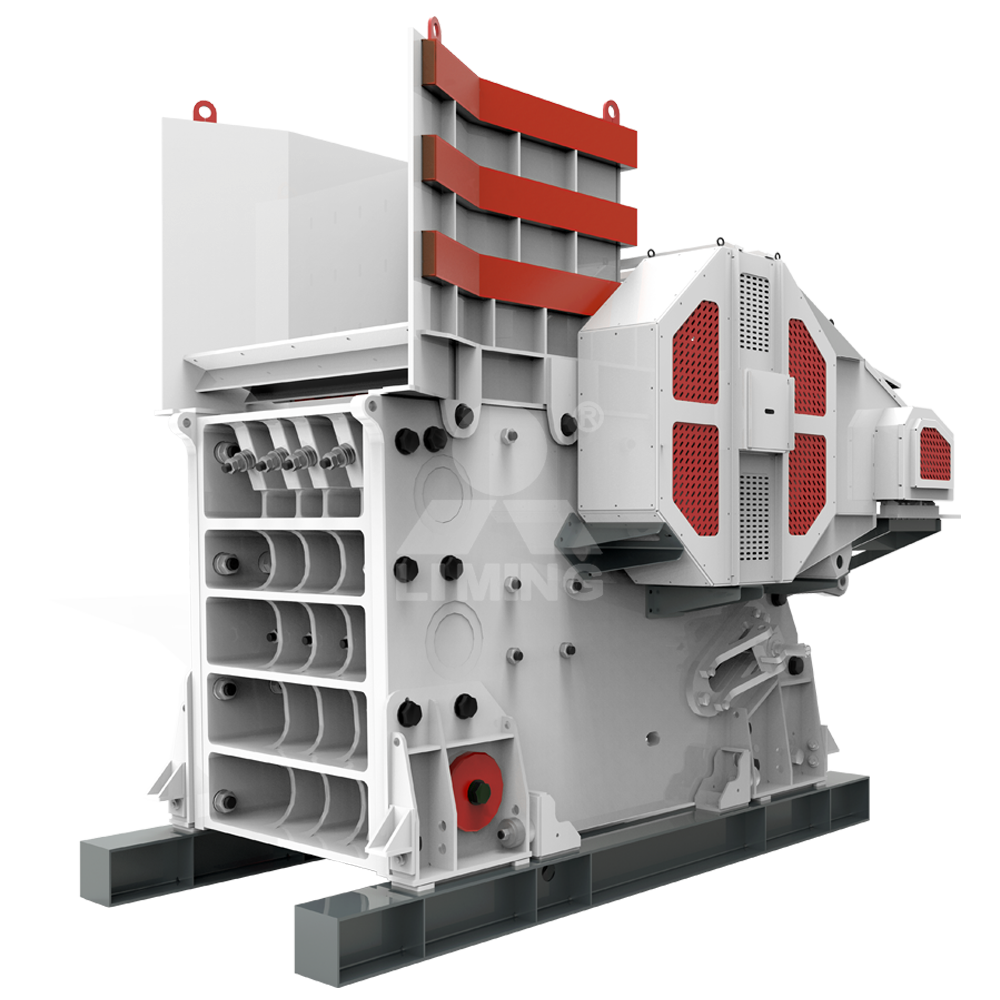

3. Impact Crushers: Masters of Shape

Ideal for softer, non-abrasive materials like limestone and recycled concrete, impact crushers excel at producing a well-shaped final product.

High-Rotor Inertia: Heavy-duty rotors are designed to maintain momentum during crushing, ensuring consistent particle size distribution even with variable feed.

Adjustable Grinding Paths: Hydraulic or mechanical adjustment of impact aprons allows operators to fine-tune the final product size without changing major components.

4. Gyratory Crushers: The High-Capacity Giants

For the world's largest open-pit mines where primary crushing capacity is measured in thousands of tons per hour.

Massive Scale Engineering: These represent the pinnacle of Chinese heavy industrial manufacturing.

Spider & Mainshaft Design: Advanced metallurgy and casting techniques are used to create these critical components to withstand decades of punishing operation..jpg)

III. Market Dynamics & Global Application

The global market for Chinese mining crushers is bifurcated but expanding rapidly.

1. Price-to-Performance Leadership:

The most significant advantage is often the cost. A Chinese-manufactured crusher can offer 80-90% of the performance of a Western-European or North American counterpart at 50-60% of the price. This value proposition is irresistible for many small-to-mid-sized mining operations, quarry owners in developing economies, and large contractors working on fixed-budget projects.

2. Penetration into Emerging Markets:

Across Africa, Southeast Asia, and South America—regions undergoing their own infrastructure development—Chinese crushers are ubiquitous. Their affordability is complemented by flexible financing options often tied to broader Chinese development projects or export-import bank loans.

3. Application Versatility:

These machines are not confined to traditional mining.

Aggregate Production: Supplying sand, gravel, and crushed stone for construction.

Metal Mining: Crushing gold-, copper-, and iron-ore at primary, secondary, and tertiary stages.

Recycling: Specialized mobile impact crushers are widely used in construction & demolition (C&D) waste recycling across Europe and North America.

Chemical & Industrial Minerals: Processing materials like phosphate rock or potash.

IV. Future Outlook & Strategic Evolution

The trajectory points towards greater sophistication beyond cost leadership.

1. Technological Integration: Leading Chinese manufacturers are aggressively integrating Industry 4.0 principles into their equipment through IoT sensors that monitor vibration temperature pressure enabling predictive maintenance reducing unplanned downtime

2 .Sustainability Focus: Development is increasingly geared towards energy efficiency through optimized crushing chambers drive systems Dust suppression noise reduction technologies are becoming standard features addressing environmental concerns

3 .After-Sales & Support Globalization: Recognizing that reliable service is as important as machine quality top-tier companies have been establishing regional parts warehouses training centers worldwide closing one traditional gap with Western competitors

4 .R&D Intensity: Investment fundamental research new materials designs composite parts hybrid power systems will allow them compete not just on price but technological innovation

V Frequently Asked Questions FAQ

Q1 Are Chinese crushers reliable long-term investments?

A While early-generation machines faced criticism modern units from established brands demonstrate significantly improved reliability Critical factors include proper model selection correct installation regular maintenance using genuine spare parts

Q2 How does after-sales service compare internationally?

A This varies dramatically Top-tier manufacturers now offer comprehensive global service networks comparable many Western brands However smaller lesser-known factories may provide limited support due diligence supplier selection paramount

Q3 What about intellectual property IP concerns?

A Industry has evolved Many leading Chinese companies now hold extensive patent portfolios develop original designs While reverse engineering certain components still occurs focus has shifted towards independent innovation meet specific market demands

Q4 Can I get custom-designed solutions?

A Yes major manufacturers increasingly offer customization options feed material final product requirements throughput capacity specific site conditions demonstrating move from mass-production bespoke engineering solutions

VI Engineering Case Studies Brief Overviews

Case Study 1 Iron Ore Mine Australia

A mid-tier iron ore producer facing cost pressures replaced its aging primary jaw crusher with a heavy-duty model from a leading Chinese supplier Resulted 15% increase throughput due larger feed opening reduced energy consumption per ton while capital expenditure was 40% lower than competing quotes Machine has been operational three years meeting all performance metrics

Case Study 2 Granite Quarry Nigeria

A quarry supplying aggregates local road construction project utilized complete crushing screening plant from single Chinese supplier Turnkey solution included vibrating feeder jaw cone crushers vibrating screens Project completed on schedule within budget plant continues operate producing high-quality aggregates supporting regional infrastructure development

Case Study 3 C&D Waste Recycling Germany

A European recycling company purchased mobile tracked impact crusher specifically designed processing concrete asphalt debris Machine’s fuel efficiency low noise emissions met strict EU regulations Its flexibility moving between sites operational cost savings provided rapid return investment demonstrating competitiveness even highly regulated mature markets

Conclusion

Chinese mining crusher industry journey from domestic supplier global powerhouse remarkable testament country’s manufacturing prowess Driven initially by internal demand it has matured into sophisticated technologically capable sector offering compelling value proposition worldwide As continues invest innovation service its role shaping global resource extraction construction industries will only grow more significant