coke crusher dimensions

# Coke Crusher Dimensions: Key Specifications and Considerations

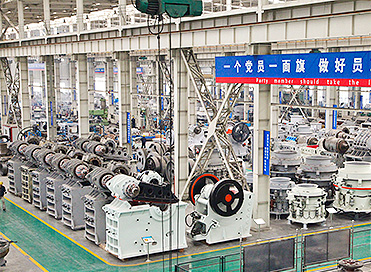

Coke crushers are essential equipment in industries such as steel production, petroleum refining, and chemical processing, where coke (a carbon-rich solid derived from coal) must be crushed to specific sizes for efficient use. Selecting the right coke crusher requires careful consideration of dimensions, capacity, and operational requirements.

## Common Coke Crusher Types and Their Dimensions

1. Double Roll Crusher

- Typical Dimensions:

- Width: 500–2000 mm

- Diameter: 600–1500 mm

- Length: Varies based on capacity (typically 1000–3000 mm)

- Features: Adjustable gap between rolls for controlled particle size output.

2. Jaw Crusher

- Typical Dimensions:

- Feed Opening Width: 400–1500 mm

- Feed Opening Length: 600–2000 mm

- Overall Machine Length: 1500–4000 mm

- Features: High crushing ratio, suitable for primary crushing.

3. Hammer Crusher

- Typical Dimensions:

- Rotor Diameter: 800–2000 mm

- Rotor Width: 600–2500 mm

- Overall Height: Up to 3000 mm

- Features: High-speed impact crushing for finer coke particles. .jpg)

4. Impact Crusher

- Typical Dimensions:

- Rotor Diameter: 1000–2000 mm

- Machine Width/Length: Varies by model (often compact designs)

- Features: Suitable for secondary crushing with adjustable output size.

## Key Factors Influencing Coke Crusher Dimensions

1. Capacity Requirements – Higher-capacity crushers generally have larger dimensions to accommodate greater throughput.

2. Feed Size – Larger feed openings require wider and taller crushers.

3. Output Particle Size – Fine crushing may necessitate multi-stage crushers with varying dimensions.

4. Installation Space – Compact designs are preferred where space is limited (e.g., refineries).

## Conclusion

Choosing the right coke crusher involves balancing dimensional constraints with operational needs such as capacity, feed size, and desired output specifications. Manufacturers often provide customized solutions based on application requirements, ensuring optimal performance in industrial settings