concassage machinne in korea

1. PAIN-POINT DRIVEN OPENING

Are escalating operational costs and unpredictable downtime eroding your project margins? For plant managers and contractors in Korea’s demanding aggregates, mining, and construction recycling sectors, suboptimal crushing performance has a direct, measurable impact on the bottom line. Common challenges include:

- Excessive Downtime for Maintenance: Frequent liner changes and mechanical adjustments can halt your entire processing line for hours, costing thousands per hour in lost production.

- Inconsistent Product Gradation: Fluctuations in final aggregate size can lead to product rejection, re-processing costs, and failure to meet strict project specifications.

- High Energy Consumption per Ton: Older or inefficient crushing technology directly inflates your most variable operating cost: power.

- Rapid Wear Part Degradation in Abrasive Materials: The cost of wear parts like mantles, concaves, and jaws is significant, but the labor and downtime for their replacement is often more costly.

- Inflexibility to Feed Variation: Can your primary crusher handle unexpected oversize or fluctuating hardness without bogging down or requiring manual intervention?

The central question is: how can you achieve higher throughput of in-spec material while controlling wear costs and maximizing plant uptime? The answer lies in selecting a modern concassage machinne in korea engineered for the specific rigors of your local operational environment.

2. PRODUCT OVERVIEW

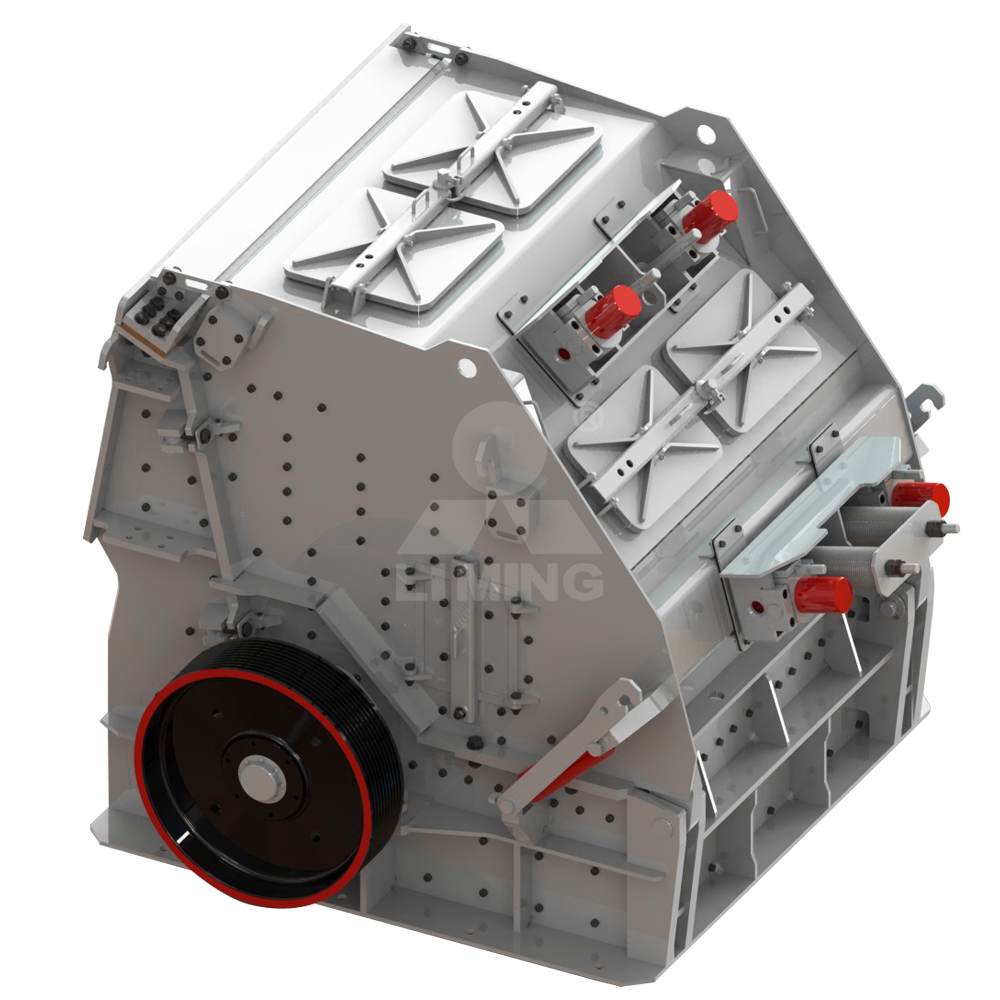

This content details a high-performance stationary primary jaw crusher series, specifically configured for the Korean market. Designed as the robust first stage in mineral processing and aggregate production lines, it transforms raw quarry feed into manageable material for secondary crushing.

Operational Workflow:

- Feed Intake: Large dump trucks deposit run-of-quarry material (up to specified feed size) directly into the crusher’s vibrating grizzly feeder (VGF).

- Primary Reduction: The VGF removes fines and directs oversize material into the crushing chamber where a powerful oscillating jaw exerts extreme compressive force against a fixed jaw.

- Size-Graded Discharge: Crushed material exits through an adjustable discharge opening (CSS), with the size determined by your downstream process requirements.

Application Scope: Primary crushing of granite, basalt, limestone, and recycled concrete/demolition waste. Ideal for fixed-plant installations in quarrying, large-scale construction projects, and mining operations.

Limitations: Not designed as a standalone finishing unit; requires secondary and tertiary stages for producing most specification aggregates. Maximum feed size and capacity are bound by model selection.

3. CORE FEATURES

Deep-Crushing Chamber & Optimized Kinematics | Technical Basis: Increased nip angle and longer crushing stroke | Operational Benefit: Enables higher throughput of hard, abrasive stone while reducing the risk of bridging or choke-feeding | ROI Impact: Up to 15% higher throughput compared to previous-generation models with similar footprint.

Heavy-Duty Fabricated Frame with Stress-Relieved Steel | Technical Basis: Finite Element Analysis (FEA) designed structure with integrated motor mounts | Operational Benefit: Provides exceptional durability under cyclical loading, minimizing frame fatigue and alignment issues over a 20+ year service life | ROI Impact: Reduces long-term structural maintenance costs and protects major capital investment.

Hydraulic Adjustment & Clearing System | Technical Basis: Dual-acting hydraulic cylinders for toggle tension and chamber clearing | Operational Benefit: Allows operators to adjust crusher setting (CSS) or clear a stall in minutes from a remote location, enhancing safety | ROI Impact: Cuts downtime for routine adjustments by approximately 70% versus manual shim systems.

Bolt-On Wear Liners & Modular Cheek Plates | Technical Basis: High-grade manganese steel sections secured with mechanically locked bolts | Operational Benefit: Simplifies liner replacement; individual sections can be changed without removing entire jaw holders | ROI Impact: Lowers liner inventory costs and reduces mean time to repair (MTTR) by up to 40%.

Integrated Motor & Drive Guarding | Technical Basis: Factory-installed guards compliant with Korean industrial safety standards (KOSHA) | Operational Benefit: Delivers a turnkey safety solution, reducing on-site fabrication time and ensuring operator protection from day one | ROI Impact: Accelerates commissioning timeline and mitigates risk of compliance-related work stoppages.

4. COMPETITIVE ADVANTAGES

| Performance Metric | Industry Standard (Legacy Plant) | This concassage machinne in korea Solution | Advantage (% improvement) |

|---|---|---|---|

| Availability (Scheduled Runtime) | ~85% (due to adjustment/clearing delays) | >94% (with hydraulic assist & modular wear parts) | +9% |

| Cost per Ton (Wear Parts) | Baseline (100%) | Approximately 85% of baseline (optimized kinematics reduce abrasive sliding) | -15% |

| Energy Consumption (kWh/tonne) | Baseline (100%) | Approximately 92% of baseline (efficient direct drive & optimized chamber) | -8% |

| CSS Adjustment Time | 60-90 minutes (manual shims) | <10 minutes (hydraulic adjustment) | -85% |

5. TECHNICAL SPECIFICATIONS

- Capacity Range: Model-dependent, from 150 to 800 tonnes per hour.

- Feed Opening: Sizes from 800mm x 550mm up to 1200mm x 830mm.

- Power Requirement: Electric motor drive from 75 kW to 160 kW; configured for Korean industrial voltage standards (380V/60Hz).

- Material Specifications: Main frame fabricated from S355JR steel; jaw plates available in premium Mn18Cr2 or Mn22Cr2 alloy for extended life in abrasive conditions.

- Physical Dimensions: Design prioritizes service access; typical footprint ranges from L8m x W3m x H3m to L10m x W4m x H4m.

- Environmental Operating Range: Engineered for Korea’s climate; standard lubrication systems are rated for operation from -15°C to +45°C ambient temperature. Optional cold-weather packages available.

6. APPLICATION SCENARIOS

#### Granite Quarry Operation, Gyeonggi-do | Challenge: Meeting high demand for road base material was constrained by daily downtime for manual crusher setting adjustments on an aging primary unit. Inconsistent output also caused bottlenecks at the secondary cone crushers. | Solution: Installation of a new hydraulic-adjust primary jaw crusher as the cornerstone concassage machinne in korea upgrade within their existing circuit.| Results: CSS adjustment time reduced from over an hour per shift to under ten minutes. This contributed to a documented 12% increase in daily throughput while producing a more consistent -200mm product for downstream processing.

#### Construction Waste Recycling Facility, Busan | Challenge: Processing heavily reinforced concrete demolition waste resulted in catastrophic uncrushable material events (rebar tangles), requiring full-day shutdowns to manually clear the chamber.| Solution: Deployment of a heavy-duty jaw crusher equipped with an automated hydraulic clearing system specifically selected as their primary concassage machinne in korea.| Results: Chamber clearing operations now take less than two minutes via remote control after triggering an overload sensor. Annual availability increased by over 300 hours, directly translating into higher volumes of saleable recycled aggregate.

7. COMMERCIAL CONSIDERATIONS

Equipment pricing is structured across three tiers based on size/capacity (Standard Duty, Heavy Duty, Extra Heavy Duty) with clear cost-to-tonnage efficiency scaling..jpg)

Optional Features Include: Automated lubrication systems, wear part monitoring sensors, dust suppression ring kits compatible with local water recycling systems.

Service Packages are offered separately, including scheduled inspection plans (Care Basic), guaranteed parts availability plans (Care Plus), or full-site performance contracts (Care Performance).

Financing options are available through partnered institutions covering capital lease agreements tailored for multi-year infrastructure projects common among Korean engineering contractors.

8. FAQ

Q1. Is this concassage machinne compatible with our existing secondary cone crushers and conveyors?

Field data shows these units are engineered as direct replacements or new primary stages within existing circuits; our engineering team provides interface drawings confirming fitment based on your plant layout during pre-sales consultation.

Q2. What is the expected operational impact during installation?

A well-planned installation typically requires between five days depending on foundation readiness; we provide detailed site preparation guidelines months prior delivery date minimize disruption schedule

Q3. Are spare parts readily available within Korea?

Yes critical wear parts manganese steel castings bearings hydraulic components held regional warehouse Seoul ensure lead times under five business days emergency orders

Q4. How does pricing compare total cost ownership versus cheaper imported alternatives?

While initial capital outlay may be higher industry testing demonstrates that lower energy consumption reduced wear part costs significantly higher availability deliver lower cost per tonne processed over typical five-year period

Q5. What training provided our operators maintenance staff?

Commissioning includes comprehensive two-day hands-on training covering safe operation routine maintenance troubleshooting procedures conducted both Korean English languages

Q6. Can this equipment handle wet sticky feed common during Korea’s rainy season?

Standard grizzly feeder configuration handles moderate moisture optional stepped grizzly deck scalping screen recommended severe conditions prevent packing chamber