equipment for gypsum mining

Essential Equipment for Efficient and Sustainable Gypsum Mining

Gypsum mining, a critical industry supplying raw material for construction, agriculture, and manufacturing, relies on a specialized fleet of equipment to extract, process, and transport the mineral efficiently and safely. The selection of machinery is dictated by the mining method—whether open-pit or underground—and focuses on maximizing productivity while minimizing environmental impact. This article outlines the core equipment used across different stages of gypsum mining, from initial excavation to final loading for transport..jpg)

Core Equipment by Mining Stage

The gypsum mining process follows a logical sequence, with specific machinery deployed at each phase.

-

1. Drilling & Blasting: While gypsum is relatively soft, controlled blasting is often used in large-scale open-pit operations to fracture the rock mass.

- Equipment: Rotary blast hole drills are primary. Track-mounted drills offer mobility on uneven benches.

- Purpose: To create patterns of holes for explosive charges, breaking the gypsum into manageable fragments.

-

2. Excavation & Loading: This is the primary production stage where broken gypsum is gathered.

- Equipment: Hydraulic excavators (with rock buckets) and wheel loaders are most common. In some cases, draglines or bucket-wheel excavators may be used for large, stratified deposits.

- Purpose: To dig, scoop, and load the fragmented gypsum onto haulage vehicles.

-

3. Haulage: Transporting ore from the pit to the primary crusher or stockpile.

- Equipment: Off-highway dump trucks (rigid or articulated) are standard. For shorter distances or in-contour mining, conveyor belt systems offer an efficient alternative.

- Purpose: To move high volumes of material with minimal cycle time.

-

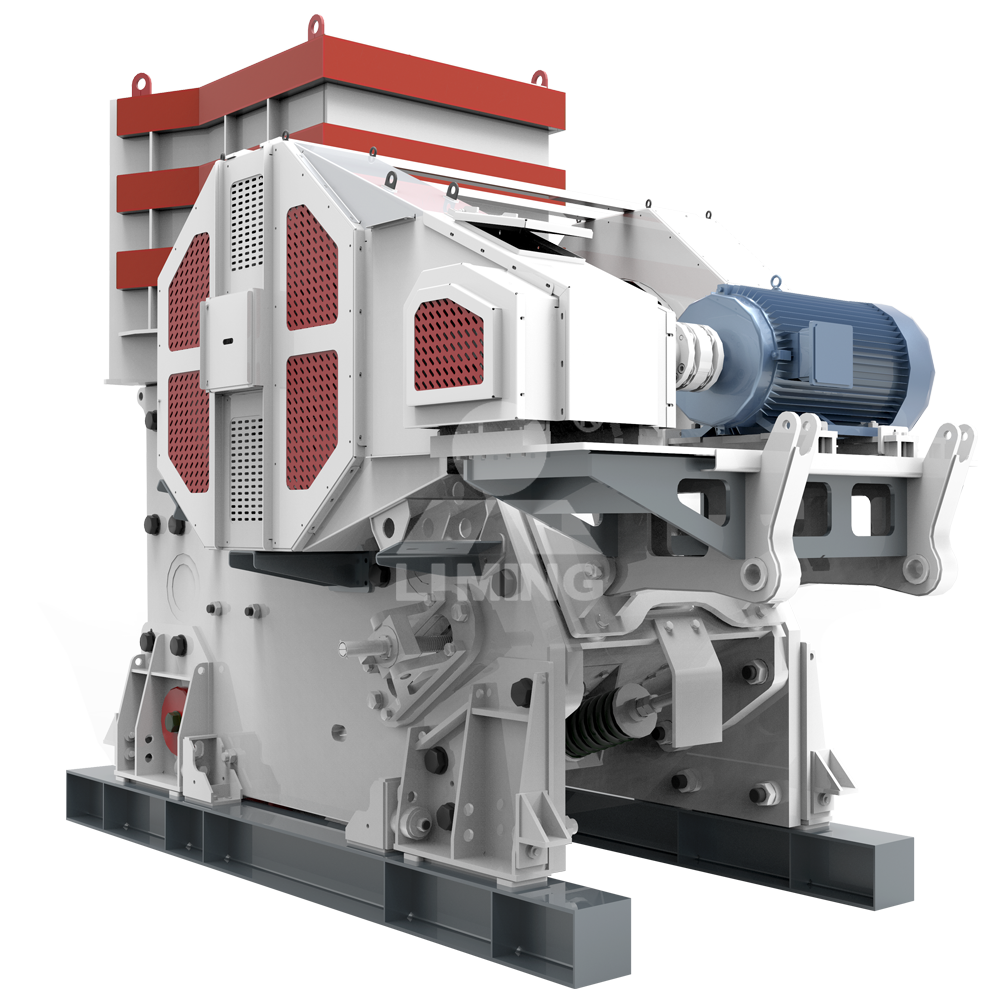

4. Crushing & Sizing: Primary crushing often occurs at the mine site to reduce transportation costs.

- Equipment: Jaw crushers (for primary crushing) and impact crushers or cone crushers (for secondary reduction). Screens are used to separate sizes.

- Purpose: To reduce mined rock to a uniform size suitable for transport or further processing in a plaster/board plant.

Equipment Selection: Open-Pit vs. Underground Mining

The choice between surface and underground mining depends on deposit depth and overburden thickness. The equipment strategy varies significantly.

| Aspect | Open-Pit Mining | Underground Mining (Room-and-Pillar Method) |

|---|---|---|

| Primary Excavation | Hydraulic Excavators, Wheel Loaders | Continuous Miners, Roadheaders |

| Haulage | Large Dump Trucks (e.g., 40-100 ton capacity) | LHDs (Load-Haul-Dump vehicles), Shuttle Cars |

| Drilling | Rotary Blast Hole Drills | Jumbo Drills for development & bolt holes |

| Ground Support | Minimal (slope stability management) | Roof Bolters, Shotcrete machines |

| Key Advantage | Higher production rates, lower cost per ton | Minimal surface disturbance, access to deeper deposits |

Real-World Case: Optimizing Haulage with Conveyors

A prominent example of innovative equipment application comes from a major gypsum producer in Nova Scotia, Canada. Facing rising fuel costs and seeking to reduce its carbon footprint at its open-pit operation, the company invested in an in-pit crushing and conveyor system. A mobile primary crusher was installed directly in the pit. Excavators load gypsum directly into the crusher, which then feeds onto a series of conveyor belts that transport the sized material several kilometers to the processing plant. This solution eliminated dozens of diesel truck journeys per day, significantly cutting fuel consumption, emissions, road maintenance costs, and safety risks associated with truck haulage.

FAQs

-

Why are continuous miners not used in all underground gypsum mines?

While highly efficient in soft-to-medium strength deposits like coal and salt, continuous miners can generate significant fines when cutting harder crystalline gypsum. The room-and-pillar method using drilling/blasting or roadheaders allows for better control over fragment size and reduces yield loss to ultra-fine material unsuitable for board production. -

What is the single most important factor when selecting loading equipment?

Material density and fragmentation size. Gypsum has a lower density (~2.3 t/m³) compared to metallic ores. Therefore, bucket capacity must be chosen based on volumetric throughput rather than weight limit alone. A bucket sized for iron ore would be underutilized for gypsum. -

Is dust control a major consideration for gypsum mining equipment?

Absolutely. Gypsum dust can be a nuisance and an explosive hazard in confined spaces (like mills). Equipment in processing areas is often fitted with integrated dust suppression systems (water sprays) or connected to dust collection units. In open pits, water trucks are routinely used to dampen haul roads. -

How has equipment technology improved safety in gypsum mining?

Modern machinery incorporates numerous safety features: proximity detection systems to prevent collisions around large vehicles; automated braking; falling object protection structures (FOPS) for cabs; and telematics that monitor machine health to prevent catastrophic failures. In underground mines, remote-operated LHDs can now be used in unstable areas. -

Can older mines retrofit new technology onto existing equipment?

Yes, retrofitting is common to extend asset life and improve performance.Common retrofits include adding GPS-based fleet management systems for tracking location and productivity; upgrading engine controls to meet newer emission standards;and installing camera/monitor systems around vehicles to eliminate blind spots