manufaturing of stone quarry machine

# The Manufacturing Process of Stone Quarry Machines

## Introduction

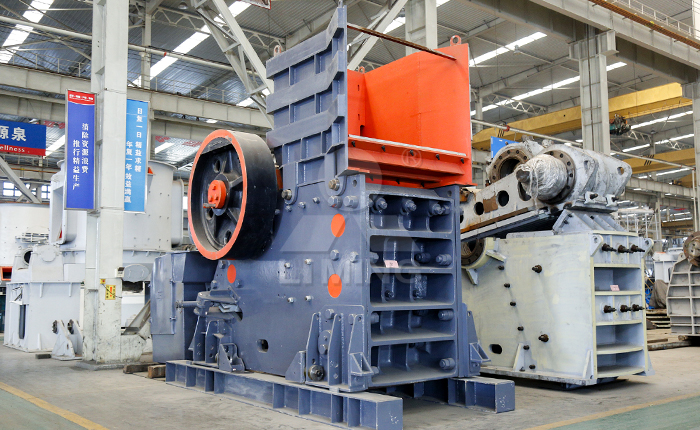

Stone quarry machines are essential equipment in the mining and construction industries, used for cutting, drilling, and extracting natural stone from quarries. These machines must be robust, precise, and efficient to handle the demanding conditions of stone extraction. The manufacturing process involves several stages, from design and material selection to assembly and quality testing.

## 1. Design and Engineering

The production of stone quarry machines begins with detailed engineering and design. Engineers use CAD (Computer-Aided Design) software to create precise blueprints that meet industry standards. Key considerations include:

- Machine Type: Wire saws, chain saws, diamond wire cutters, drilling rigs, or hydraulic splitters.

- Power Requirements: Electric, diesel, or hydraulic power systems.

- Material Compatibility: Granite, marble, limestone, or other hard stones. .jpg)

## 2. Material Selection

High-quality materials are crucial for durability and performance:

- Steel Alloys: Used for structural components due to their strength and resistance to wear.

- Diamond Tools: Cutting wires and drill bits embedded with industrial diamonds for precision cutting.

- Hydraulic Systems: High-pressure hoses and pumps for efficient power transmission.

## 3. Fabrication of Components

Machining processes include:

- Laser Cutting & CNC Machining – For precise metal parts like frames and gears.

- Welding & Assembly – Heavy-duty welding ensures structural integrity under stress.

- Electroplating & Coating – Anti-corrosion treatments extend machine lifespan in harsh environments.

## 4. Assembly & Integration

Skilled technicians assemble components such as:

- Cutting Mechanisms (diamond wires or chains) mounted on motorized tracks.

- Hydraulic/Pneumatic Systems connected to control panels for smooth operation.

- Safety Features like emergency stops and protective guards installed per regulations.

## 5. Quality Control & Testing

Before delivery, each machine undergoes rigorous testing:

- Performance Checks – Simulated quarry conditions test cutting speed and accuracy.

- Durability Tests – Stress tests ensure long-term reliability under heavy loads.

- Safety Inspections – Compliance with ISO or OSHA standards is verified.

## 6. Packaging & Distribution

Finished machines are disassembled (if large) for shipping:

- Protective coatings prevent rust during transit.