rubber and usable tyre crusher plants suppliers in china

Industry Background: The Challenge of End-of-Life Tyres

The global automotive industry, supported by a massive logistics and transportation network, generates an enormous volume of end-of-life tyres (ELTs) annually. The World Business Council for Sustainable Development estimates that nearly 1 billion tyres reach the end of their service life each year. Historically, these ELTs have posed a significant environmental challenge, often ending up in landfills where they become fire hazards and breeding grounds for pests, or are stockpiled, creating long-term ecological burdens.

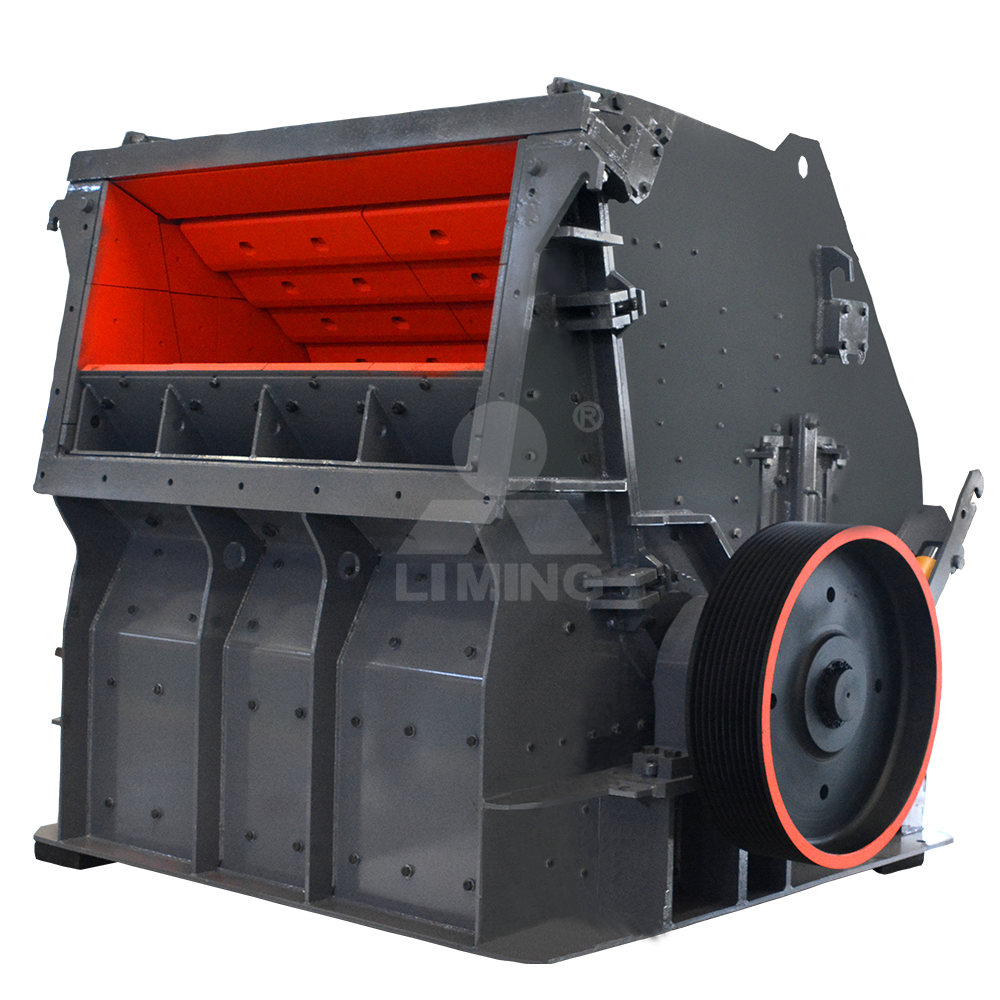

The core challenge lies in the very properties that make tyres useful: their durability and complex composition of rubber, steel, and textile fibres. Simply dumping them is unsustainable, and incineration without energy recovery is wasteful and polluting. This has driven the need for advanced recycling technologies that can transform this waste stream into a valuable resource. In this context, tyre crusher plants have emerged as a critical piece of machinery, serving as the primary size-reduction system that prepares ELTs for downstream processing into rubber crumb, reclaimed rubber, or tire-derived fuel (TDF).

Core Product/Technology: Deconstructing the Modern Tyre Crusher Plant

What makes a Chinese tyre crusher plant both "rubber and usable"?

A modern tyre crusher plant from leading Chinese suppliers is not a single machine but an integrated system designed for maximum efficiency, output quality, and automation. The goal is to sequentially break down whole tyres into clean, separated, and sized materials.

-

Key Features:

- Whole Tyre Processing: Capable of handling entire passenger and truck tyres without pre-processing.

- Integrated Steel Separation: Utilizes powerful magnetic separators to remove steel cords (the bead and belt wire) after each crushing stage, ensuring high-purity rubber output.

- Fiber Removal Systems: Employs air classifiers or vibrating screens to separate textile fibres from the rubber granulate.

- Multi-Stage Size Reduction: The process typically involves several stages to achieve the desired final product size.

-

System Architecture & Workflow:

- Primary Shredding: Whole tyres are fed into a heavy-duty, slow-speed shear shredder. This machine uses high-torque rotors with cutting hooks to tear tyres into large 2-5 inch (50-150 mm) chips.

- Bead Wire Extraction: The shredded chips pass through a bead wire separator, which pulls out the rigid steel bead ring.

- Secondary Granulation: The steel-free chips are then processed in a granulator or cracker mill, which further reduces them to smaller pieces (10-20 mm).

- Magnetic Separation & Fiber Sorting: A cross-belt magnet removes fine steel cords liberated during granulation. Subsequent screening and air separation remove textile fibres.

- Fine Grinding (Optional): For applications requiring very fine rubber powder (30-120 mesh), the granules may be fed into a fine grinding mill or cryogenic pulverizer.

-

Innovation Drivers: Leading Chinese manufacturers are focusing on:

- Automation & PLC Control: Reducing labor costs and improving consistency through programmable logic controllers that monitor machine load and optimize throughput.

- Energy Efficiency: Developing direct-drive systems and optimizing rotor designs to lower kWh consumption per ton of processed material.

- Tooling Durability: Using specialized alloys for cutting blades and screens to extend service life and reduce maintenance downtime.

Market & Applications: From Waste to Worth

The output from these advanced crusher plants—clean rubber crumb and granulate—opens up diverse markets beyond low-value tire-derived fuel.

| Application | Product Form | Key Benefit |

|---|---|---|

| Modified Asphalt | 10-20mm Granulate / Crumb Rubber | Enhances road durability, reduces noise, and improves skid resistance. |

| Sports Surfaces | 1-4mm Granulate | Creates safe, elastic surfaces for playgrounds, running tracks, and artificial turf infill. |

| Moulded Products | 10-40 Mesh Powder | Used in manufacturing floor tiles, speed bumps, mats, and other industrial rubber products. |

| Reclaimed Rubber | Fine Powder | Partially replaces virgin rubber in new tyre manufacturing and automotive parts, closing the material loop. |

| Pyrolysis Feedstock | 10-30mm Chips | Provides uniform feedstock for pyrolysis plants that convert rubber into oil, carbon black, and gas. |

The primary benefits driving adoption include:

- Environmental Compliance: Helps governments and waste management companies meet stringent landfill diversion targets.

- Economic Value Creation: Transforms a disposal cost into a revenue stream through the sale of secondary raw materials.

- Resource Conservation: Reduces the demand for virgin rubber and fossil fuels used in synthetic rubber production.

Future Outlook: Smarter Systems Deeper Integration

The evolution of tyre recycling technology is moving towards greater intelligence and circularity.

- Digitalization & IoT: Future plants will be equipped with extensive sensor networks feeding data into cloud platforms. This will enable predictive maintenance (alerting operators to wear before failure), real-time optimization of production parameters, and traceability of material batches.

- Higher Purity Standards: As markets like tire-to-tire recycling grow,the demand for ultra-clean rubber powder with near-total removal of steeland fibre will intensify.This will drive innovation in separation technologies,e.g.,advanced optical sorting.

- Integration with Pyrolysis & Devulcanization: Crusher plants will be increasingly designed as the front-end for more advanced chemical recycling processes.Pyrolysis breaks down rubber into its constituent chemicals,and devulcanization reverses the vulcanization process,making recycled rubber nearly equivalent to virgin material.Crusher plants that produce optimally sizedand clean feedstock will be crucialfor these processes'economic viability.

- Modular & Scalable Designs: Suppliers are likely to offer more modular plants that can be easily scaled up as business grows or reconfiguredto produce different output specifications,cateringto smalland medium-sized enterprises.

FAQ Section.jpg)

-

What is the typical investment range for a complete tyre crusher plant from China?

The cost varies significantly based on capacityand automation level.A small-to-medium plant processing 1-2 tons per hour can range from $80,000to $200,000.Larger,fully automated lines with capacities exceeding5 tons per hour can cost$500,000or more.It is criticalto obtain detailed quotations that include shipping,installation,and commissioning services. -

How do I choose between a normal temperature system anda cryogenic system?

Normal temperature (ambient) systems are suitablefor producing granularrubber from 10to 40 mesh.They are more commonand have lower capitaland operating costs.Cryogenic systems use liquid nitrogento embrittle the rubber,enabling productionof very fine powder (80-120 mesh).They offer higher purity but at a significantly higher operational cost due to nitrogen consumption.The choice depends entirely on your target marketand product specifications. -

What kindof after-sales service canbe expectedfrom Chinese suppliers?

Reputable suppliers offer comprehensive after-sales support,which typically includes remote technical guidance,detailed operation manuals,and readily available spare parts.Many provide overseas engineer installationand commissioning servicesfor an additional fee.It is imperative to verifythe supplier's service capability,spare parts inventory,and language support before purchasing. -

Whatis therecovery rateof rubbergranulatefrom passenger car tyres?

A typical passenger car tyre consists of approximately 55-60%rubber,15-25%steel,and15-20%textile.A well-configured plant can achievea rubbergranulate recovery rateof around50-55%of the total input weight by mass.The remaining weightis recoveredas steel scrap(valuable)and textile fibre(often usedas a refuse-derived fuelor disposedof).

Case Study / Engineering Example: Transforming ELTs into Playground Safety

-

Client & Challenge: A municipal solid waste management companyin Southeast Asia was facing growing stockpilesof end-of-life tyres anda public mandate to reduce landfill waste by30%.They soughta solutionthat could not only process the tyres but also createa high-value productfor local markets.

-

Solution Implementation: The company selecteda semi-automatic tyre crusher plant froma leading Chinese supplier.The system was configured with:

- A dual-shaft primary shredder

- A rotary screenwith magnetic separator

- A secondary granulator

- A fiber separation unit (cycloneair separator)

The plant was designed fora throughputof1.5 tonsper hour,producing cleanrubber granulatein two sizes:10-20mmfor loose-fill playground surfacingand1-4mmfor moulded sports floor tiles.

-

Measurable Outcomes:

- Within12 months of operation,the plant successfully processed over3,000 tonsof ELTs,diverting them from landfills.

- The company establisheda new revenue streamby sellingthe producedrubber granulateto local sports facility contractorsand construction material manufacturers.

- The purity ofthe final productwas measuredat >99。5%rubber content(by weight),meeting international standardsfor playground safety surfacing materials。

- The project achieveda return on investmentin under3 years througha combinationof landfill tip fee avoidanceandrevenuefrom material sales,demonstratingclear economicandenvironmental viability。