sand quarry sale

Industry Background

The global construction industry, valued at over $13 trillion, is fundamentally dependent on a steady and reliable supply of aggregates, with sand being the most extracted solid material in the world after water. Sand quarries are critical assets, providing the essential raw material for concrete, asphalt, glass, and land reclamation. However, the industry faces significant and interconnected challenges:

- Environmental Scrutiny and Regulation: Unsustainable extraction rates have led to severe ecological damage, including riverbank erosion, loss of biodiversity, and groundwater depletion. This has prompted stringent environmental regulations globally, complicating the permitting process for new quarries.

- Resource Depletion: Not all sand is suitable for construction. The high-demand industrial-grade sand found in specific geological formations is a finite resource. The depletion of easily accessible sites forces operators to consider more remote or geologically complex locations.

- Operational Inefficiency: Traditional quarry operations often rely on legacy practices for resource assessment, extraction planning, and logistics. This can lead to suboptimal yield, inconsistent material quality, high fuel consumption, and elevated operational costs.

- Market Volatility: The construction sector is cyclical. Quarry owners must navigate fluctuating demand while managing high fixed costs for land, equipment, and labor.

These pressures necessitate a more intelligent, data-driven approach to quarry management and transaction.

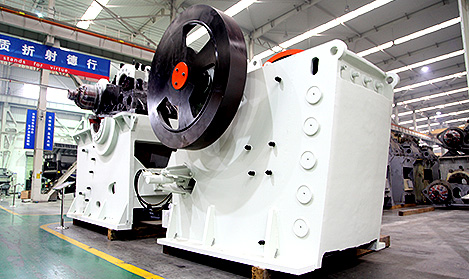

Core Product/Technology: The Modern Sand Quarry Sale Platform

The sale of a sand quarry has evolved from a simple land transaction to a complex process requiring detailed technical and financial due diligence. A modern approach leverages integrated technology to de-risk the investment and maximize asset value. The core components of this platform include:

- 3D Geological Modeling and Resource Verification: Utilizing advanced geophysical surveys (e.g., seismic refraction) and core drilling data to create high-fidelity digital twins of the quarry reserve. This model accurately quantifies the volume and grades the quality of the sand deposit.

- Automated Extraction Planning Software: Sophisticated software analyzes the geological model to generate an optimal extraction sequence (mine plan). This maximizes recovery rates, minimizes waste stripping, and ensures a consistent product quality over the life of the quarry.

- Integrated Logistics and Fleet Management (IoT): On-site equipment fitted with IoT sensors provides real-time data on production rates, fuel consumption, machine health, and haul truck movements. This data is fed into a central dashboard for live operational oversight.

- Environmental Compliance Monitoring: Continuous monitoring systems track noise levels, dust emissions (PM2.5/PM10), and water quality in real-time. Automated reporting features streamline compliance with regulatory bodies.

This integrated technological architecture transforms a static asset into a dynamic, data-validated operation that is far more attractive to sophisticated buyers such as private equity firms or large construction conglomerates.

Market & Applications.jpg)

This modern approach to quarry sales serves a diverse range of industries that rely on high-quality silica sand or construction aggregates.

| Industry | Application | Key Benefit |

|---|---|---|

| Construction & Concrete | Production of ready-mix concrete, pre-cast elements | Guaranteed consistency in gradation and purity ensures structural integrity of concrete. |

| Glass Manufacturing | High-purity silica sand for container, flat, and specialty glass | Precise resource modeling confirms the chemical composition (low iron content) required for glassmaking. |

| Hydraulic Fracturing | Proppant sand used in oil & gas well stimulation | Validates reserves of high-strength, round-grained "frac sand" essential for well productivity. |

| Land Development & Reclamation | Fill material for infrastructure projects and coastal protection | Accurate volume estimation allows for precise bidding on large-scale civil engineering contracts. |

The primary benefits for buyers include reduced investment risk through verified reserves; predictable operational costs through optimized planning; faster time-to-production; and enhanced environmental credentials.

Future Outlook

The trajectory of the quarry industry points towards greater automation and sustainability.

- Full Automation: The future will see wider adoption of autonomous haul trucks and drilling rigs controlled by centralized AI systems that adjust operations in real-time based on sensor data.

- Advanced Analytics & AI: Predictive analytics will be used not just for equipment maintenance but also for dynamic resource modeling—predicting changes in material quality as extraction progresses.

- Circular Economy Integration: Quarries will increasingly be viewed as temporary land uses with post-closure plans that include rehabilitation into nature reserves or renewable energy sites (e.g., solar farms). The sale process will begin to account for this end-of-life value.

- Blockchain for Provenance: To meet demands for sustainable sourcing from major contractors (e.g., government infrastructure projects), blockchain technology will be used to provide an immutable record of a material's origin and its adherence to environmental standards.

FAQ Section

What key due diligence factors should I consider when buying a sand quarry?

A comprehensive due diligence process must extend beyond financials to include: verified reserve estimates from an independent geologist; all active environmental permits and any historical liabilities; clarity on mineral rights versus surface rights; proximity to transportation infrastructure; and a realistic life-of-mine operational plan.

How does technology impact the valuation of a quarry?

Technology directly impacts valuation by de-risking the asset. A quarry with a digitally verified reserve model demonstrating 20 years of high-quality material is less risky than one with estimates based on outdated methods. Similarly,a fully permitted site with automated systems promises lower future operating costsand higher profitabilityjustifyinga premium valuation

What are common environmental liabilities associated with a quarry purchase?

Potential liabilities can include water contamination from fuel or oil spills sedimentation of local waterways from runoff violationsof air quality standards relatedto dustand non-compliancewith mandatedrehabilitation planspost-closure A thorough Phase I Environmental Site Assessmentis critical

Can an older legacy quarry be upgraded with modern technology

Yes retrofittingis often feasibleand can deliversignificant returns on investment Initial upgrades typically focuson fleet management IoT sensorsfor critical equipmentand automatedweighingand ticketing systems These provideimmediate gainsin operational visibilityandefficiencypavingthe wayfor more advancedautomationlater

Case Study / Engineering Example

Project: Divestiture of the "Rockingham County Silica Sand Quarry" by a mid-tier mining company.

Challenge: The seller needed to demonstrate the long-term value and operational viability of a 500-acre quarry asset to attract serious bids from national aggregate producers.The existing operation relied on manual processes,and reserve estimates were basedon decade-old surveys

Implementation:

1.A third-party engineering firm was engagedto conducta state-of-the-artresource assessmentThis included:

- A high-density seismic surveyto mapthe deposit structure

- Over 50 new core drillingsamplesanalyzedfor grain size distribution shape chemical purityand compressive strength

- Developmentof a detailed3D block modelclassifyingreservesinto Provenand Probablecategories

2.The datawas integratedinto mine planningsoftwareto generatea 25-yearextraction phasingplanoptimizingproduct mixhigh-purity glass sandvs construction sand

3.An IoT-based fleet managementsystemwas installedon a trial basisto providepotential buyerswith real-worlddataon load cycleshaul timesand potential efficiencygains

Measurable Outcomes:

- Increased Reserve Confidence: The independent audit increasedthe proven reserveestimateby 18% comparedto historical figuresdirectly increasingthe asset'svaluable inventory

- Enhanced Bidding Competition: Five qualified bids were receivedfrom top-tier companiesattractedbythe transparentdata-richpackage

- Final Sale Price: The quarry soldfora final price15% abovethe initial expectationbasedon legacy dataThe buyer specifically citedthe comprehensivegeologicalmodeland clearoperational roadmapas key factorsin their valuation

- Reduced Due Diligence Period: The pre-packagedtechnical datashortenedthe buyer'sdue diligenceperiodby approximately60% acceleratingthe transactionclose