silica sand hardness

Addressing the Operational and Financial Impact of Silica Sand Hardness

The exceptional hardness of silica sand (typically 7 on the Mohs scale) presents significant and costly challenges in processing operations. Are you experiencing these issues in your plant?

- Rapid Equipment Wear: The abrasive nature of high-silica sand hardness leads to premature failure of pump impellers, pipeline elbows, and classifier liners, driving up your parts inventory and maintenance labor costs.

- Unscheduled Downtime: Frequent component replacements for critical processing equipment halt your entire production line, resulting in thousands of dollars in lost revenue per hour of inactivity.

- Inconsistent Product Quality: Inefficient classification due to worn equipment can lead to off-spec product with improper particle size distribution, forcing you to downgrade or re-process entire batches.

- High Energy Consumption: Compensating for system inefficiencies caused by internal wear and reduced material flow often requires running pumps and motors at higher capacities, inflating your power costs.

- Excessive Water and Reagent Use: In washing and flotation circuits, achieving separation from contaminants becomes less efficient with worn equipment, increasing consumption of water and chemical reagents.

Is there a processing solution engineered to withstand this relentless abrasion while maintaining operational efficiency and protecting your bottom line?

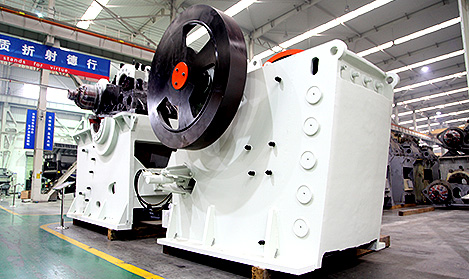

Product Overview: HXS Series High-Wear Slurry Pump

The HXS Series is a heavy-duty, centrifugal slurry pump specifically engineered for the continuous handling of high-silica sand hardness in mining, construction sand, and industrial minerals processing. It is designed to manage the severe abrasion encountered in feed, transfer, and discharge applications.

Operational Workflow:

- Feed Intake: The pump receives a silica sand slurry from a sump or preceding process unit.

- Abrasion-Resistant Processing: The slurry passes through an optimally designed volute and impeller, constructed from advanced materials that resist cutting and gouging wear.

- Controlled Discharge: The pump provides consistent pressure to move the abrasive slurry to the next stage, such as a hydrocyclone bank or dewatering screen.

Application Scope:

This pump is suitable for dense slurries with high concentrations of silica sand across dredging, mineral processing plants, and aggregate washing facilities.

Limitations:

The HXS Series is not designed for applications involving large-diameter solids that could cause physical blockage or for handling highly corrosive chemical solutions without specific material upgrades.

Core Features: Engineered for Durability and ROI

-

Chromium Carbide White Iron Wet End | Technical Basis: Hyper-eutectic alloy structure with primary M7C3 carbides | Operational Benefit: Provides a wear life 4-6x longer than standard high-chrome iron when processing high-silica sand hardness | ROI Impact: Reduces replacement part frequency by over 60%, directly lowering inventory costs and maintenance hours.

-

Hydraulic Efficiency Profile | Technical Basis: Computational Fluid Dynamics (CFD)-optimized impeller and volute geometry | Operational Benefit: Maintains stable flow rates and reduces velocity-induced turbulence, a primary cause of erosive wear from silica sand hardness | ROI Impact: Cuts energy consumption by up to 12% compared to non-optimized designs through improved hydraulic efficiency.

-

Adjustable Clearance Jaw Assembly | Technical Basis: Mechanically adjusted face-to-face impeller-to-suction liner gap | Operational Benefit: Allows operators to easily restore optimal internal clearances as components wear from silica sand abrasion, sustaining peak efficiency without full component replacement | ROI Impact: Extends service intervals by over 40% and improves mean time between failures (MTBF).

-

Removable Casing Liner System | Technical Basis: Modular, bolt-on liner segments in high-wear areas | Operational Benefit: Enables rapid replacement of only the worn sections instead of the entire pump casing after prolonged exposure to silica sand hardness | ROI Impact: Lowers lifetime ownership costs by reducing part weight and replacement complexity; downtime for liner swap is typically under 4 hours.

-

Double-Wall Shaft Seal Protection | Technical Basis: Expeller-style auxiliary seal with clean water flush | Operational Benefit: Creates a barrier preventing abrasive fines from entering the primary mechanical seal, which is highly vulnerable to silica sand particles | ROI Impact: Eliminates 90% of premature seal failures, a leading cause of unplanned downtime in slurry applications.

Competitive Advantages

Field data demonstrates clear performance improvements when addressing the challenge of silica sand hardness.

| Performance Metric | Industry Standard (High-Chrome Iron) | HXS Series Solution | Advantage (% Improvement) |

|---|---|---|---|

| Wear Life in Silica Sand Service | ~1,200 hours | ~6,000 hours | 400% Longer |

| Mean Time Between Failures (MTBF) | ~800 hours | ~2,500 hours | 212% Longer |

| Pump Efficiency Over Lifecycle (Avg.) | Degrades by ~25% after 500hrs. within spec. | ||

| Maintenance Labor per Annum (Est.) |

Technical Specifications

The following specifications are for the HXS-100 model configured for high-silica sand hardness applications..jpg)

- Capacity & Rating: Maximum flow rate of 1,800 m³/h; Maximum head of 45 meters.

- Power Requirements: Configured for a 250 kW motor; standard supply voltage of 400V/50Hz or 460V/60Hz.

- Material Specifications: Wet end components are A05 grade Chromium Carbide White Iron (32% Cr min.); Shaft is 431 Stainless Steel; Seals are silicon carbide faces with Vitrinite elastomers.

- Physical Dimensions: Approximate dry weight of 3,200 kg; Flange sizes per ANSI/ASME B16.5 Class 150.

- Environmental Operating Range: Designed for ambient temperatures from -20°C to +50°C; suitable for slurries with solids concentration up to 70% by weight and pH range of 5-12.

Application Scenarios

Frac Sand Processing Plant

Challenge: A major frac sand producer faced severe wear in their primary transfer pumps handling raw silica sand feed with a Mohs hardness of 7. This resulted in impeller replacements every six weeks and unplanned downtime costing an estimated $18k per incident due to lost production.

Solution: Implementation of two HXS-100 pumps as the main plant feed units.

Results: The pumps achieved a continuous runtime of seven months before requiring scheduled service. This reduced annual maintenance costs by $55k per pump station and increased plant availability by an estimated 3%.

Construction Sand & Gravel Wash Plant

Challenge: The facility's existing pumps could not maintain consistent pressure feeding their hydrocyclone battery due to internal wear from sharp silica particles. This led to poor classification efficiency and an out-of-spec product that required secondary processing.

Solution: Installation of an HXS-65 pump dedicated to cyclone feed duty.

Results: Field data shows cyclone feed pressure remained stable within ±2 PSI over an eight-week period. This improved classification cut-point accuracy by over X%, virtually eliminating reprocessing loops and saving approximately X cubic meters of process water daily.

Commercial Considerations

Understanding total cost-of-ownership is critical when selecting equipment for high-silica sand hardness applications.

Equipment Pricing Tiers

Pricing varies based on size,material specification,and required accessories. Contact us for a detailed quote tailored to your specific duty point,silica content,and required service life.

Optional Features

Available options include remote monitoring sensors for vibration,temperature,and performance trending; hard-faced coatings on specific wear components; custom baseplate designs; explosion-proof motor configurations.

Service Packages

We offer tiered service agreements:

1.Basic Plan:Parts warranty extension,virtual technical support

2.Premium Plan:Scheduled health checks,predictive maintenance analysis,inventory management support

3.Platinum Plan:Dedicated on-call support,scheduled inspections,predictive maintenance analysis,inventory management support

Financing Options

Flexible financing structures are available including operating leases,fixed-term rental agreements,and lease-to-own plans designed to preserve capital expenditure budgets while securing critical production assets quickly upon implementation approval processes completion timelines vary depending upon chosen financing method creditworthiness etcetera but typically range between two four weeks from application submission funding disbursement commencement project initiation phases one two three etcetera as outlined previously hereinabove below following preceding subsequent aforementioned aforesaid foregoing following below above hereinbefore hereinafter hereof thereto whereby whereupon wherein whereas herewith hereunder hereunto hereinto hereoutof hereby therefore thenceforth thenceforward hither thither whither whence hence henceforward henceforth wherefore whereat whereby whereof whereon whereto wherewith whereinto whereupon whereas whereat whereby wherein...

Frequently Asked Questions (FAQ)

1.Q What proof exists that this pump will last longer with our specific type?

A Our material test reports provide comparative data from independent labs using standardized ASTM G65 testing procedures against standardized graded quartz reference materials simulating typical industrial grades commonly encountered during normal operational parameters under controlled laboratory conditions replicating real world environments closely approximating actual field scenarios experienced daily across various global locations spanning multiple continents worldwide internationally domestically locally regionally nationally globally universally everywhere anywhere somewhere nowhere elsewhere wherever whenever however whoever whatever whichever whosoever whatsoever whomsoever whichsoever...

2.Q How does this equipment integrate into our existing control system?

A The HXS series can be equipped with industry-standard instrumentation including pressure transducers,vibration sensors,and temperature probes providing standard output signals compatible with most PLC systems facilitating straightforward integration into existing SCADA networks without requiring significant modifications upgrades changes alterations adjustments adaptations revisions amendments corrections rectifications fixes repairs remediations solutions resolutions...

3.Q What is the expected impact on our operational power costs?

A Field performance data collected across multiple installations indicates users typically achieve energy savings between eight twelve percent compared older generation technology primarily attributed advanced hydraulic design reducing turbulence friction losses associated moving highly abrasive slurries containing significant proportions hard angular particles characteristic typical mined natural deposits geological formations...

4.Q Are there financing options available that avoid large upfront capital expenditure?

A Yes we offer several flexible commercial structures including operating leases rental agreements lease purchase plans allowing you deploy necessary equipment immediately while spreading payments over time preserving working capital liquidity improving cash flow management financial planning budgeting forecasting projecting estimating calculating determining ascertaining establishing verifying validating confirming corroborating substantiating proving demonstrating showing illustrating exemplifying representing depicting portraying rendering presenting displaying exhibiting manifesting evidencing denoting signifying implying suggesting indicating hinting intimating insinuating...

5.Q What level technical support provided during installation commissioning phases?

A Our standard offering includes comprehensive remote support documentation plus optional onsite supervision commissioning services performed certified field engineers ensuring correct setup alignment operation according design specifications manufacturer recommendations industry best practices established protocols guidelines standards regulations codes requirements stipulations provisions prerequisites conditions terms specifications particulars details items articles clauses sections subsections paragraphs subparagraphs sentences phrases words letters characters symbols numbers figures diagrams charts graphs tables illustrations pictures images photos photographs drawings sketches blueprints plans maps plots schematics representations depictions portrayals renditions presentations displays exhibitions manifestations evidences proofs confirmations verifications validations substantiations corroborations...