small vsi impact crusher

The Compact Power of Small VSI Impact Crushers

In the world of aggregate processing and mineral reduction, the quest for a superior cubical product has long been a primary objective. Traditional compression crushers, like jaw and cone crushers, are workhorses known for their high capacity and ability to handle large feed material. However, the fracture mechanism in these machines often produces flaky or elongated particles, which are less desirable for high-strength concrete and asphalt applications. This industry-wide need for improved particle shape created a niche for a different technology: the Vertical Shaft Impact (VSI) crusher. While large-scale VSIs are common in major quarries, a significant evolution has been the refinement and growing adoption of the small VSI impact crusher.

The Core Technology: Impact Crushing Redefined

A small VSI crusher operates on the same fundamental principle as its larger counterparts: accelerating rock against rock. The core mechanism involves a high-speed rotor that flings material into a stationary crushing chamber lined with anvils or other wear parts. The key differentiator from horizontal shaft impactors is the truly vertical orientation of the rotor, which creates a high-velocity vortex of material-on-material impact.

This rock-on-rock action is central to its value proposition. As particles collide with each other at high speed, they break along natural fissures and weaknesses. This process, known as autogenous crushing, minimizes wear on the machine's metal components while simultaneously shaping the particles into a more cubical form. The smaller versions of these machines encapsulate this technology into a portable or semi-portable footprint, often with rotors under 40 inches in diameter and powered by electric motors typically ranging from 75 to 300 hp.

Critical to its function is the precise control over rotor speed. By adjusting the rotational velocity, operators can fine-tune the final product's gradation and shape. A higher speed generally produces a finer output with enhanced cubicity. Furthermore, many small VSIs feature a cascading system where some feed material is diverted to create a protective rock lining on the inner chamber walls, further reducing wear costs—a crucial consideration for operational economics.

Market Position and Diverse Applications

The small VSI crusher does not compete directly with large primary crushers. Instead, it carves out its essential role in specific market segments where flexibility, product quality, and mobility are paramount.

Its primary application is as a tertiary or quaternary crusher. In this stage of a crushing circuit, feed material has already been reduced to a manageable size by primary and secondary units. The small VSI then takes this pre-crushed aggregate and transforms it, improving its shape for critical end-uses. This is invaluable in producing concrete and asphalt chips where angular, interlocking particles provide greater structural integrity.

Beyond traditional quarries, these compact units are indispensable in several specialized fields:

Recycling: They are highly effective in processing reclaimed concrete and asphalt into high-value recycled aggregates. The ability to produce a well-shaped product from demolition waste opens significant economic opportunities.

Industrial Minerals: In processing materials like glass, slag, or certain abrasive minerals, the controlled impact action of a small VSI can achieve precise sizing with minimal contamination.

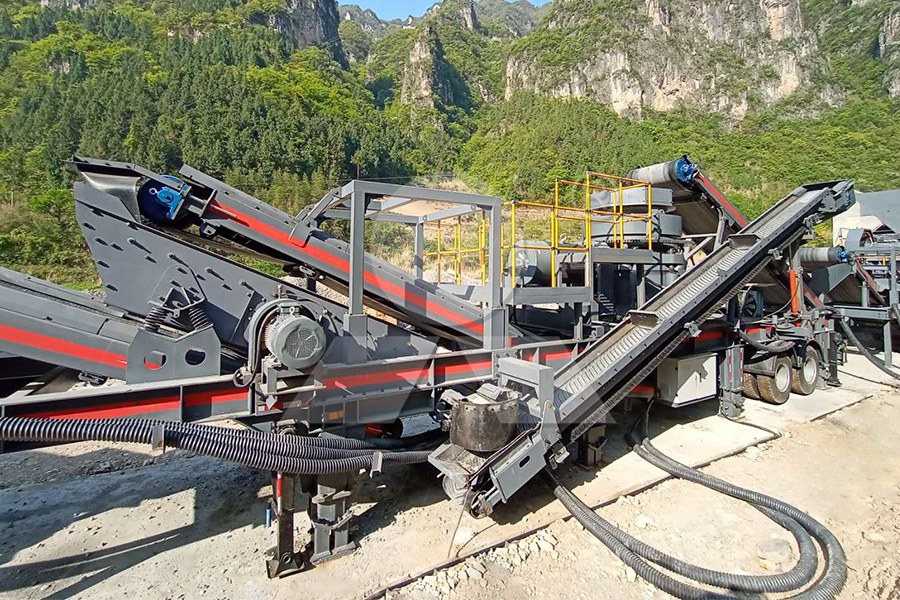

Mobile Contract Crushing: Their relatively compact size and weight make them ideal for mounting on portable chassis setups. Contract crushing companies can transport these units from site to site, processing material where it lies, which drastically reduces trucking costs for their clients.

Specialty Sand Production: For producing fine aggregate specifically engineered for applications like golf course bunkers or masonry sand, the shaping capability of a VSI is unmatched.

Operational Considerations: Weighing Advantages Against Challenges

The decision to deploy a small VSI crusher involves balancing its distinct benefits against its operational demands.

Advantages:

Superior Product Shape: This remains its single greatest advantage, leading to stronger end-products and higher sale prices for aggregates.

Versatility: With adjustable rotor speed and various chamber configurations, one machine can often produce multiple product specifications.

Reduced Wear Costs in Certain Applications: The rock-on-rock principle minimizes metal-to-metal contact when properly configured.

Compact Footprint: It fits into existing plants where space is constrained or forms the heart of a highly mobile setup.

Challenges:

Higher Wear Costs in Abrasive Applications: When processing very abrasive materials without sufficient cascading feed, wear part consumption can be significant and must be carefully managed.

Limited Feed Size: They are not designed to accept large rocks; consistent feed size control from upstream processes is critical.

Higher Energy Consumption per Ton: The high-speed rotor requires more horsepower per ton of output compared to some compression crushers.

Sensitivity to Moisture: Sticky or clay-bound material can clog the crushing chamber and reduce efficiency.

Future Trajectory

The trajectory for small VSI technology points toward greater efficiency and intelligence. We are seeing increased integration of automation systems that monitor power draw, bearing temperature, and vibration in real-time. These systems can automatically adjust feed rates or trigger maintenance alerts to prevent catastrophic failures.

Material science is another frontier. The development of more durable alloys and composite materials for rotors, tips, and anvils directly extends service life and lowers operating costs. Furthermore,the drive towards electrification and hybridization in mobile plant design aligns perfectly with the smaller VSI's power profile,making them candidates for future energy-reducing innovations.The demand for high-specification aggregatesand sustainable recycling practices will only solidifythe roleof this compact yet powerful machine.

---

Frequently Asked Questions (FAQ)

Q: How does product from a small VSI differ from that of a cone crusher?

A: A cone crusher compresses rock between a mantle and concave liner,fracturing it along natural lines but often creating more elongated or flaky particles.A VSI uses high-speed impact,causing rocks to break against each other.This results in amore cubical,fractured particle thatis highly valuedfor its strengthin concreteand locking propertiesin asphalt.

Q: What is the typical maintenance schedule like?

A: Maintenanceis heavily influenced bythe abrasiveness ofthe feed material.Wear parts like rotor tipsand anvils may need inspection every 40-80 hoursin harsh conditionsand replacement every few hundred hours.Regular greasingof bearingsand monitoringof drive beltsare standard weeklyor daily tasks.Vibration analysisis increasingly usedfor predictive maintenance.

Q: Can it handle damp or clay-rich material?

A: Thisis achallenge.Sticky materials tendto buildup inthe crushing chamber,inhibitingthe rock-on-rock actionand reducing throughputand product quality.In such cases,a grizzly feederor scalping screento remove finesbeforethe crusheris almost mandatory.Some modelsoffer cascade system adjustmentsorto help mitigate thisissue.

Q: What does "closed rotor" vs "open rotor" design mean?

A: An open rotor designis primarilyfor rock-on-rock crushing,maximizingthe autogenous processand minimizingwear.It’s idealfor non-abrasiveor moderately abrasive materials.A closed rotor designencloses theeach tableto createa more pronounced shelf.This configurationis betterfor handling highly abrasive materialsand forcingsmore direct impactbetween rockand wear parts,whensuperior shapingis less criticalthan managing extreme abrasion.

---

Engineering Case Study

Project: Urban Highway Overpass Reconstruction

Location: Metropolitan area with strict aggregate specifications.

Challenge: A contract crushing company was tasked with processing 50,ooo tons of reclaimed concrete pavement (RCP) from an old highway intoa base course material meeting state DOT specificationsfor particle shape(indexof <15% elongated particles).The operation hadto be conductedon asite adjacentto the active highwaywith limited spaceand strict noise/dust controls.The final product neededto be consistentandin specfor immediate reuseon the project.

Solution: A track-mounted mobile plant was configuredwitha magnetic separatorfor removing rebar,a small vibrating screenfor scalpingsmaller fines,andasmalVSI impactcrusherasthe tertiary unit.The pre-crushed RCPwas fed intotheV SIwheretherock-on-rock action effectively broke downthe old cement pastefromthe aggregateand reshapedthe angular particles.The closed-circuit designwith thereturnof oversize material ensureda consistentgradation.

Outcome: ThesmallV SIcrusher successfully produced over 45,ooo tons ofhigh-quality,cubical recycled aggregate that exceededDOTshape requirements.The mobility ofthe plant allowedfor quick setupand teardown,andthe compact footprint fit perfectlyonthe constrainedsite.The superior shapeofthe resultingmaterial contributedto adenser,better-compacted road base,directly supportingthe project’s quality goalswhile significantly reducinglandfill wasteand virginmaterial costs