stein zerkleiner machine

What is a Stein Zerkleiner Machine?

A Stein Zerkleiner Machine, directly translated from German as a "stone crushing machine," is a heavy-duty industrial equipment designed to reduce large rocks, stones, and ores into smaller, more manageable sizes. These machines are the workhorses of the mining, quarrying, and construction industries, forming the foundational stage of material processing for everything from concrete aggregate to precious metal extraction..jpg)

This article will delve into the industry background, core technology, market applications, and future trends of these essential machines.

---

Industry Background: Why Do We Need to Crush Stone?

The need to break rock is as old as civilization itself, but the industrial revolution mechanized the process. Today, the global economy runs on crushed stone. It is the literal bedrock of modern infrastructure.

Construction Aggregate: The largest application. Crushed stone is mixed with cement and sand to produce concrete and used as a base layer for roads, railways, and foundations.

Mining and Mineral Processing: Ores containing valuable metals (like gold, copper, and iron) are crushed to liberate the target minerals from the waste rock before further processing.

Chemical and Fertilizer Industries: Phosphate rock and other minerals are crushed to create fertilizers.

Environmental Recycling: Concrete and asphalt from demolished structures are crushed and reused as recycled aggregate, reducing landfill waste and conserving natural resources.

The demand is immense. According to a report by Grand View Research, the global construction aggregates market size was valued at USD 375.2 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 3.7% from 2022 to 2030. This growth directly fuels the demand for efficient stone crushing machinery.

---

The Core of the Machine: How Do Different Crushers Work?

Not all rocks are the same, and neither are all crushing needs. The "core" of stone crushing technology lies in applying massive mechanical force through different principles. The main types of crushers can be categorized by their crushing action:

1. Jaw Crusher (Backenbrecher)

This is often the primary crusher, handling the initial reduction of large boulders.

How it Works: It uses two vertical jaws—one stationary and one that moves back and forth in a squeezing motion—to compress and break the rock.

Best For: Hard, abrasive materials; primary crushing stage; high capacity.

Analogy: Like a giant nutcracker for rocks.

2. Gyratory Crusher (Kegelbrecher)

Similar in function to a jaw crusher but used for even higher capacity primary crushing.

How it Works: A central vertical gyrating spindle inside a concave hopper crushes the rock as it moves downwards.

Best For: Very high-capacity primary crushing in large mines and quarries.

Analogy: A giant pestle spinning inside a massive mortar.

3. Cone Crusher (Konusbrecher)

This is typically a secondary or tertiary crusher, producing finer, more uniform-shaped products.

How it Works: Similar to a gyratory crusher but with a steeper head angle and a parallel zone between the crushing members for finer output.

Best For: Secondary/Tertiary crushing; producing fine aggregates; hard and abrasive stones.

Analogy: A more precise version of the gyratory crusher for finishing work.

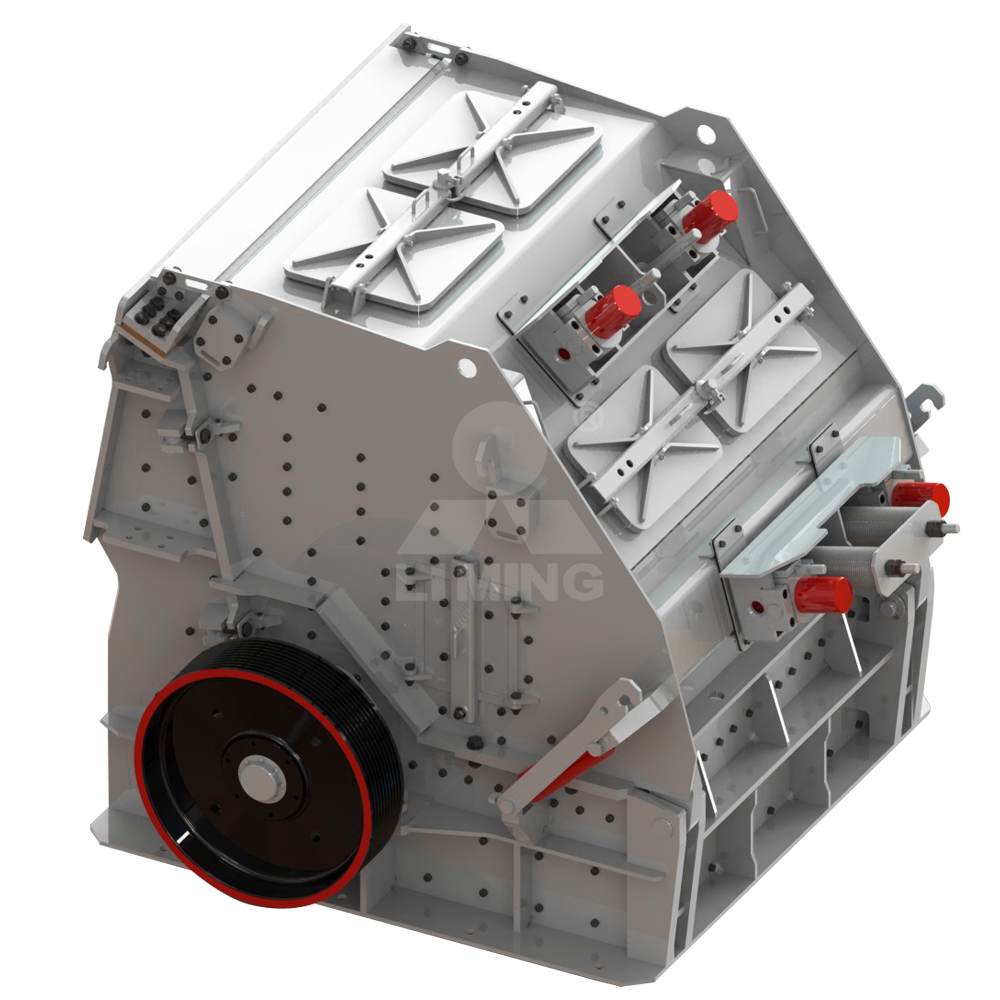

4. Impact Crusher (Prallbrecher)

These crushers use speed and impact rather than pressure to break rock.

How it Works: Rotors with blow bars or hammers spin at high speed, striking incoming rocks and throwing them against impact plates.

Best For: Softer, less abrasive materials like limestone; recycling (concrete, asphalt); excellent product shape control.

Analogy: A high-speed hammer mill for stones.

Comparison Table: Core Crusher Types

| Feature | Jaw Crusher | Cone Crusher | Impact Crusher |

| :--- | :--- | :--- | :--- |

| Crushing Principle | Compression | Compression | Impact |

| Best Application Stage| Primary | Secondary/Tertiary | Secondary/Tertiary/Recycling |

| Input Material Hardness| High - Very High | High - Very High | Low - Medium |

| Product Shape | Less uniform, slabby | Cubical & uniform | Very cubical & uniform |

| Operating Cost | Lower | Medium-Higher | Medium |

| Wear & Tear | On jaw plates | On mantles & concaves | On blow bars & impact plates |

---

Market Dynamics: Who Makes Them and What's Driving Innovation?

The global stone crusher market is highly competitive, dominated by international players like Sandvik (Sweden), Metso Outotec (Finland), Terex Corporation (US), ThyssenKrupp (Germany), and LiuGong (China).

Key market drivers include:

1. Infrastructure Development: Massive government investments in roads, railways ("Belt and Road Initiative"), and urban development in Asia-Pacific are major growth engines.

2. Urbanization: The global shift towards cities requires constant construction, driving demand for aggregates.

3. Technological Advancement: The shift towards automation, IoT connectivity ("smart crushers"), electric/hybrid drives for sustainability.

4. Stringent Environmental Regulations: Pushing manufacturers to develop dust suppression systems, noise reduction technologies, and highly efficient electric models.

---

Applications Beyond Quarries: Where Else Are They Used?

While quarries are their most visible home, stone crushers are critical in numerous other sectors:

✅ Mining: Crushing run-of-mine ore for further processing.

Source: U.S. Geological Survey (USGS) Mineral Commodity Summaries.

Example: In a gold mine,crushed ore is leached with cyanide solutionto extract gold.

Example:In an iron ore mine,crushed material is fed into blast furnacesor processed into pellets.

Example:In aggregate production,crushed stone is screened into various sizesfor concrete mix or road base.

Example:In recycling,demolition wasteis processed into valuable recycled concrete aggregate(RCA).

Example:In agriculture,crushed limestoneis spread on fields to adjust soil pH.

---

The Future of Crushing: What's Next?

The future of Stein Zerkleiner Machines is intelligent, efficient, and green:

1. Automation & Remote Monitoring: Crushers will be increasingly operated via remote control with real-time performance data analytics to predict maintenance needs (predictive maintenance) before breakdowns occur.

2. Electric & Hybrid Drives: To reduce carbon footprint and operational costs tied to diesel fuel.

3. Advanced Wear Parts: Development of new alloys and composite materials for liners/blow bars that last longer under extreme abrasion (Reference: Studies on Tungsten Carbide composites in International Journal of Refractory Metals and Hard Materials).

4. Modular & Mobile Designs: Plug-and-play mobile crushers that can be quickly deployed on-site reduce transportation costs for material.

---

Frequently Asked Questions (FAQ)

Q1: What is the difference between primary, secondary,and tertiary crushing?

A1:

- Primary Crushing:The first stage where large run-of-mine material(up to 1-1.5m)is reducedto ~150-250mm.Uses Jaw or GyratoryCrushers.- Secondary Crushing:Takes primary-crushed materialand reducesit furtherto ~50-100mm.Uses Coneor ImpactCrushers.- Tertiary Crushing:The final stageof size reductionproducingfine aggregates(under~25mm)for specific applicationslike asphaltor concrete.Uses ConeCrushersor specializedImpactCrushers(VSI).

Q2 How much doesa stein zerkleiner machine cost?

A2:The cost varies dramaticallybasedon type size capacityand brand.A small mobile jawcrushermight startaround$100 000whilea large stationaryprimarygyratorycrusherfora majorminecan costseveral milliondollars.Totalcostof ownershipmustalso factorinfuel/electricity maintenanceand wearparts.

Q3:Whatarethemostcommonwearpartsandhowoftenaretheyreplaced?

A3:Themostcommonwearpartsare:

-JawPlates(inJawCrushers)

-Mantle&Concaves(inConeCrushers)

-BlowBars&ImpactPlates(inImpactCrushers)

Replacementfrequencydependsentirelyonmaterialabrasiveness throughputandmaterialhardness.Itcanrangefromeveryfewweekstoseveralmonths.

---

Engineering Case Study

Project: Rehabilitation of a Major Highway in Germany

Challenge: Produce over 2 million tons of high-specification road baseand asphaltaggregateswithin18months while minimizingenvironmentalimpactfromnoiseand dustnearresidentialareas.

Solution: A mobilecrushingplantwas deployedconsistingof:

-A MobileJawCrusherforprimarycrushingofquarry-runlimestone.

-A MobileConeCrusherforsecondarycrushingtoproducewell-shapedcubicalaggregates.

-The entireplantwas equippedwithadvanceddustsuppressionspraysystemsandenclosedconveyors.

Result: The projectwas completedon time.The useof modern electric-drive mobilecrushersreducednoise pollutioncomparedtodieselalternatives.Thehigh-qualitycubicalaggregateproducedledtoasuperiorroadbase requiringlessasphaltbinder savingcostsandimprovinglong-termroaddurability.Thiscaseshowshowthe rightselectionofsteinzerkleinerermachineryis criticalforsuccessinlarge-scaleinfrastructureprojects.