zenith jaw crusher china

Addressing Your Primary Crushing Challenges

Are unplanned maintenance stops and rising operational costs impacting your primary crushing circuit? For plant managers and engineering contractors, the initial reduction stage sets the tone for your entire processing operation. Common pain points with conventional jaw crushers include:

- Excessive Downtime for Maintenance: Replacing worn jaw plates can halt your production line for 12-24 hours, costing thousands in lost throughput.

- Premature Wear Part Failure: Abrasive feed material like granite or basalt can degrade standard manganese steel in weeks, not months, driving up your cost-per-tonne.

- Inconsistent Product Gradation: Fluctuations in discharge setting lead to off-spec aggregate or uneven feed for downstream processes, reducing overall plant efficiency.

- High Energy Consumption: Older crusher designs with inefficient kinematics can consume 15-20% more power, directly impacting your operating budget.

What if your primary crusher could deliver predictable performance with lower operating costs? The ZENITH Jaw Crusher from China is engineered to address these specific operational and financial challenges.

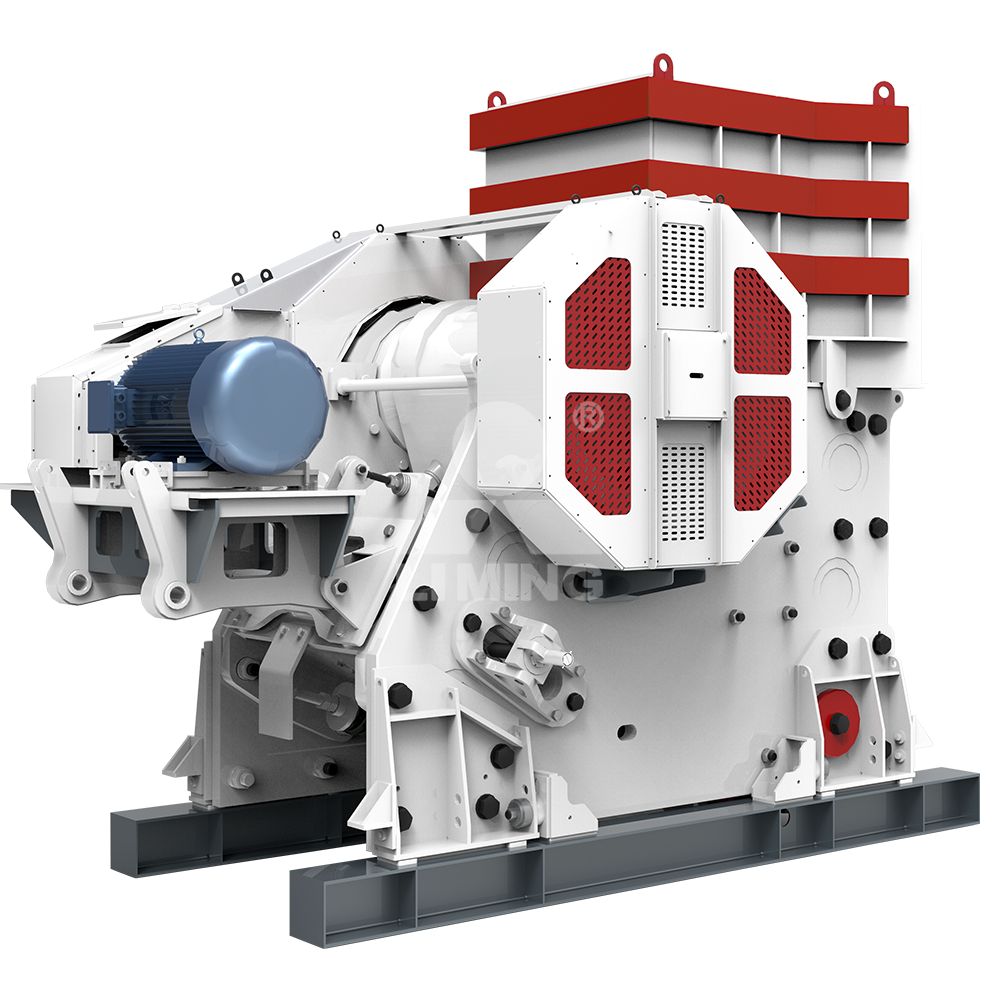

Product Overview: ZENITH Jaw Crusher

The ZENITH Jaw Crusher is a robust, stationary primary crushing machine designed for high-capacity size reduction of hard rock, ore, and construction aggregates. Its operational workflow is straightforward and reliable:

- Feed Intake: Large raw material is loaded into the vibrating feeder and directed into the crushing chamber.

- Compression Crushing: The fixed and movable jaw plates exert immense mechanical pressure, fracturing the material through compressive force.

- Discharge: Crushed product passes through the bottom discharge opening, with size controlled by the adjustable closed-side setting (CSS).

Application Scope: Ideal for primary crushing in mining (iron ore, copper ore), quarrying (limestone, granite), and heavy-duty construction waste recycling.

Limitations: Not suitable for sticky or plastic materials without prior screening or processing. Maximum feed size is dictated by the specific model's inlet dimensions.

Core Features of the ZENITH Jaw Crusher

Our engineering focus is on durability, efficiency, and serviceability to maximize your return on investment.

-

Deep Crushing Chamber & Optimized Kinematics | Technical Basis: Steeper nip angle and longer crushing cavity | Operational Benefit: Enables higher capacity and a more uniform product shape while reducing rock-on-rock wear | ROI Impact: Up to 10% higher throughput compared to conventional chambers of similar size

-

Heavy-Duty Frame Construction | Technical Basis: Fabricated from high-integrity steel plate with reinforced stress points | Operational Benefit: Provides long-term structural integrity under cyclic loading, minimizing frame fatigue and risk of catastrophic failure | ROI Impact: Extends crusher service life, protecting your capital asset investment

-

Wedge Setting Adjustment System | Technical Basis: Mechanical wedge system for closed-side setting (CSS) control | Operational Benefit: Your operators can make precise gap adjustments quickly and safely without special tools, even under full load in some configurations | ROI Impact: Reduces downtime for product changes by approximately 30%

-

High-Quality Cast Steel Jaw Plates | Technical Basis: ZENITH-manufactured jaws from modified manganese steel (Mn18Cr2) | Operational Benefit: Superior work-hardening properties increase wear life in abrasive applications | ROI Impact: Field data shows a 20-35% improvement in jaw plate life over standard Mn14 equivalents

-

Spherical Roller Bearings & Labyrinth Seals | Technical Basis: Oversized bearings housed in precision-machined pits with multi-stage sealing | Operational Benefit: Handles heavy radial and thrust loads while effectively excluding dust and contaminants | ROI Impact: Industry testing demonstrates bearing service life exceeding 25,000 hours under normal operating conditions

Competitive Advantages

The following table quantifies the performance differential between the ZENITH Jaw Crusher China solution and common industry standards.

| Performance Metric | Industry Standard | ZENITH Jaw Crusher Solution | Advantage (% Improvement) |

|---|---|---|---|

| Availability (Uptime) | ~92-94% (scheduled & unscheduled) | >96% (with planned maintenance) | >2-4% Uptime Increase |

| Wear Part Life (Abrasive Rock) | Baseline (Mn14 Jaws) | Mn18Cr2 Jaws | >25% Longer Life |

| Energy Consumption (kWh/tonne) | Baseline (Older Design) | Optimized Kinematics & Drive Design | >15% Reduction |

| Maintenance Time (Jaw Plate Change) | 16-20 Hours (Typical) | >12 Hours | >25% Faster |

Technical Specifications

These specifications are representative of a mid-range model; exact figures vary by specific ZENITH Jaw Crusher China model number.

- Capacity/Rating: Up to 1,500 tonnes per hour (model dependent)

- Feed Opening: Ranges from 750 x 500 mm to 1500 x 1200 mm

- Power Requirements: Electric motor from 75 kW to 200 kW; standard voltage options of 380V/50Hz or 460V/60Hz

- Material Specifications: Main frame: Q345B Steel; Jaw Plates: Mn18Cr2 or equivalent; Eccentric Shaft: 42CrMo forged steel

- Physical Dimensions: Approximate weight from 12 to 55 tonnes; detailed foundation drawings provided for engineering

- Environmental Operating Range: Designed for ambient temperatures from -25°C to +40°C; dust-proofing standard per IP65 rating on electrical components

Application Scenarios

Granite Quarry Operation, Southeast Asia | Challenge: Premature wear on competitor jaw plates was causing product gradation drift every 120-150 operating hours, requiring frequent shutdowns for adjustment and replacement. This resulted in high spare parts costs and unpredictable output. Solution: Implementation of a ZENITH JC Series Jaw Crusher equipped with Mn18Cr2 jaw plates. The wedge adjustment system allowed for faster CSS corrections during scheduled pauses. Results:

* 28% increase in average wear part life.

* 18 fewer hours of downtime per quarter dedicated to liner-related maintenance.

* 8% reduction in specific energy consumption due to more efficient crushing action.Iron Ore Processing Plant, Australia | Challenge: A need to debottleneck the primary circuit to handle a planned 20% increase in ROM feed tonnage without a complete structural rebuild of the crushing station. Solution: A high-capacity ZENITH Jaw Crusher was selected based on its deep chamber design offering a higher capacity-to-footprint ratio than the existing unit. Results:

* 22% increase in peak throughput achieved within the existing station footprint.

* 99.5% operational availability recorded during the first year post-installation.

* Projected payback period met within 14 months due to increased production volume.Commercial Considerations

Equipment Pricing Tiers

ZENITH Jaw Crushers are available across multiple tiers:

- Standard Series: Cost-effective models for standard duty cycles.

- Heavy-Duty Series: Premium models with enhanced features for maximum uptime in severe-service applications.

Optional Features

Common options include automated grease lubrication systems, motor starters, wear monitoring systems, and custom skid designs.

Service Packages

To protect your investment:

- Commissioning & Training Package: On-site setup and operator training.

- Planned Maintenance Agreement: Scheduled inspections and parts discounts.

- Critical Spares Kit: Pre-packaged set of essential wear and spare parts.

Financing Options

Flexible commercial terms are available through our partners, including equipment leasing structures and project-based financing solutions tailored for large capital expenditures.

Frequently Asked Questions

1. Is the ZENITH Jaw Crusher compatible with my existing secondary crushing circuit?

Yes. The discharge setting is easily adjustable to produce a range of product sizes suitable as feed for most common cone crushers and impactors. Our technical team can review your flow sheet to confirm compatibility.

2. What is the expected operational impact on my maintenance crew?

Your crew will benefit from simplified maintenance procedures. The wedge adjustment system reduces time spent on CSS changes by approximately one-third compared to traditional shim systems.

3. How does this equipment perform under high-silica content feed?

The Mn18Cr2 jaw plate option provides superior resistance against abrasive wear typical of high-silica applications like quartzite or sandstone.

4. What are typical lead times for critical spare parts?

ZENITH maintains a global supply chain network with regional warehouses supporting common spare parts availability within days or weeks depending on location.

5. Are there commercial terms that can ease upfront capital expenditure?

Yes. We offer several financing options including leasing arrangements that convert large capital outlays into manageable operational expenses over time.

6. What level of technical support is provided during implementation?

We provide comprehensive foundation drawings and technical data sheets upfront. Optional on-site commissioning supervision ensures correct installation according to design parameters.

7. Can you provide performance guarantees?

Yes. Performance guarantees regarding capacity power consumption are provided based on certified test reports using customer-supplied sample materials where feasible